广州际唯JWI200高精度双轴倾角传感器

产品简介

JWI200是一款高精度双轴倾角传感器,采用动态零位测试补偿技术保证产品快速启动,分辨率高、数据稳定、承受冲击震动能力强;内置32位ARM处理器,快速滤波运算,输出低精度数据;本倾角传感器设计有抗电磁干扰电路,系统工作稳定,能长期工作于恶劣环境中。

参数规格

| 精度 | 0.001° | 测量范围 | ±15° |

| 测量轴 | X-Y | 刷辨率 | 1Hz |

| 冲击 | 20000g, 1ms, ½sine | 响应频率 | 在DC response时为5-300HZ |

| 波特率 | 4800~11520 | 零点漂移 | 在-25~85℃时为±0.0007°/℃ |

| 工作温度 | -40~+55℃ | 存储温度 | -60~+80℃ |

| 交插灵敏度 | 在Max时为2% | 输出阻抗 | 100Ω |

| 电源电压 | 5~12VDC | 消耗电流 | ±50mA |

适用领域

- 雷达及天线角度检测

- 杆塔、桥梁、山体、大坝监测

- 工程机械臂姿态检测

- 车辆、船舶姿态检测

- 电子水平台等

- 高空平台保护

更多信息

请登录:www.jiweikeji.com

S-20WIKA S-20 高精度 高压力范围 压力变送器 精度:0.125 1600bar

| 接口尺寸: | G1/2(mm) | 加工定制: | 是 |

| 防护等级: | IP65 | 测量范围: | 0-160000(kPa) |

| 类型: | 陶瓷型压力变送器 | 防爆等级: | EX |

| 型号: | S-20 | 测量介质: | 液体 气体 |

| 精度等级: | 0.125 | 品牌: | WIKA/威卡 |

| 输出信号: | 4-20(mA) | 电源电压: | 10-30(V) |

WIKA S-20 高精度 高压力范围 压力变送器

精度:0.125 1600bar

Superior pressure transmitter for general industrial applicationsModel S-20

Applications Critical industrial applications Demanding applications in research and development Harsh environments in the process industry

Applications Critical industrial applications Demanding applications in research and development Harsh environments in the process industry

Special features Measuring ranges from 0 ... 0.4 to 0 ... 1,600 bar Non-linearity of up to 0.125 % of span Different output signals, e.g. 4 ... 20 mA, DC 0 ... 10 V,

DC 1 ... 5 V and others Market-standard electrical connections, e.g. DIN 175301-803 A angular connector Common international process connections

Description The model S-20 pressure transmitter for general industrial applications is the ideal solution for customers with demanding measuring requirements. It features a very good accuracy, a robust design and an exceptional number of variants, meaning it can be suited to the widest range of applications.

Versatile The model S-20 offers continuous measuring ranges between 0 ... 0.4 and 0 ... 1,600 bar in all the major units. These measuring ranges can be combined in almost any way with all the standard industry output signals, the most common international process connections and a wide number of electrical connections. Furthermore, it offers numerous options, such as different accuracy classes, extended temperature ranges and customer-specific pin assignments.

High quality The robust design turns the model S-20 into a very high quality product, which even the most adverse environmental conditions cannot affect. Whether with the lowest temperatures when used outdoors, with extreme shock and vibration in machine building or with aggressive media in the chemical industry, this transmitter can meet all requirements.

Availability All variants described in this data sheet are available on very short lead times. For particularly urgent demands, there is a sizeable stock available.

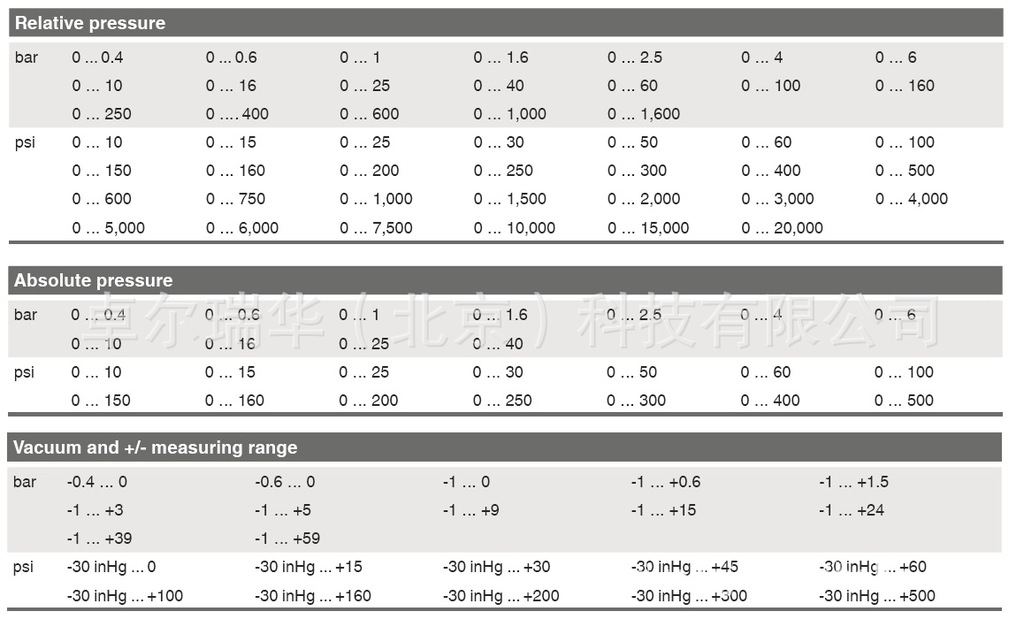

Measuring ranges

The given measuring ranges are also available in kg/cm2, kPa and MPa. Special measuring ranges between 0 ... 0.4 and 0 ... 1,600 bar are available on request. Special measuring ranges have a reduced long-term stability and increased temperature errors.

The given measuring ranges are also available in kg/cm2, kPa and MPa. Special measuring ranges between 0 ... 0.4 and 0 ... 1,600 bar are available on request. Special measuring ranges have a reduced long-term stability and increased temperature errors.

Overpressure limit The overpressure limit is based on the sensor element used. Depending on the selected process connection and sealing, restrictions in overpressure safety can result. A higher overpressure limit will result in a higher temperature error.

Measuring range < 10 bar/150 psi ≥ 10 bar/150 psi 3 times (standard) 2 times 1) (standard) 5 times 3 times 2) 3) 1) Restriction: max. 60 bar/870 psi with absolute pressure 2) Only possible for relative pressure measuring ranges ≤ 400 bar or 5,800 psi 3) Only possible for absolute pressure measuring ranges < 16 bar or 220 psi

Measuring range < 10 bar/150 psi ≥ 10 bar/150 psi 3 times (standard) 2 times 1) (standard) 5 times 3 times 2) 3) 1) Restriction: max. 60 bar/870 psi with absolute pressure 2) Only possible for relative pressure measuring ranges ≤ 400 bar or 5,800 psi 3) Only possible for absolute pressure measuring ranges < 16 bar or 220 psi

Vacuum tightness Yes

Output signal

Signal type Signal Current (2-wire) 4 ... 20 mA 20 ... 4 mA Voltage (3-wire) DC 0 ... 10 V DC 0 ... 5 V DC 1 ... 5 V DC 0.5 ... 4.5 V DC 1 ... 6 V DC 10 ... 0 V Ratiometric (3-wire) DC 0.5 ... 4.5 V

Other output signals on request.

Permissible load in Ω Current output (2-wire): ≤ (power supply - 7.5 V) / 0.023 A ≤ (power supply - 11.5 V) /

0.023 A (with optional settling time of 1 ms) Voltage output (3-wire): > maximum output voltage / 1 mA Ratiometric output (3-wire): > 4.5k

Signal limiting (option) 4 ... 20 mA: Zero point: 3.6 mA 1), 3.8 mA, 4.0 mA Full scale: 20 mA, 21.5 mA, 23 mA DC 0 ... 10 V: Full scale: DC 10 V, DC 11.5 V 1) Not possible in combination with zero point adjustment by the customer

Voltage supply

Power supply Maximum power supply for cULus approval: DC 35 V (DC 32 V with heavy-duty connector) Current output (2-wire) 4 ... 20 mA: DC 8 ... 36 V (DC 12 ... 36 V with optional settling time of 1 ms) 20 ... 4 mA (inverted): DC 8 ... 36 V Voltage output (3-wire) DC 0 ... 10 V: DC 12 ... 36 V DC 0 ... 5 V: DC 8 ... 36 V DC 1 ... 5 V: DC 8 ... 36 V DC 0.5 ... 4.5 V: DC 8 ... 36 V DC 1 ... 6 V: DC 9 ... 36 V DC 10 ... 0 V: DC 12 ... 36 V Ratiometric output (3-wire): DC 0.5 ... 4.5 V: DC 5 V ±10 %

Dissipation loss Current output (2-wire): 828 mW (22 mW/K derating of the dissipation loss with ambient temperatures ≥ 100 °C) Voltage output (3-wire): 432 mW

Current supply Current output (2-wire): Current signal, max. 25 mA Voltage output (3-wire): max. 12 mA

Reference conditions (per IEC 61298-1)

Temperature 15 ... 25 °C

Atmospheric pressure 860 ... 1,060 mbar

Humidity 45 ... 75 % relative

Power supply DC 24 V DC 5 V with ratiometric output

Mounting position Calibrated in vertical mounting position with pressure connection facing downwards.

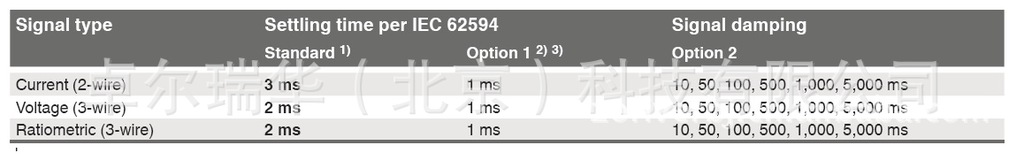

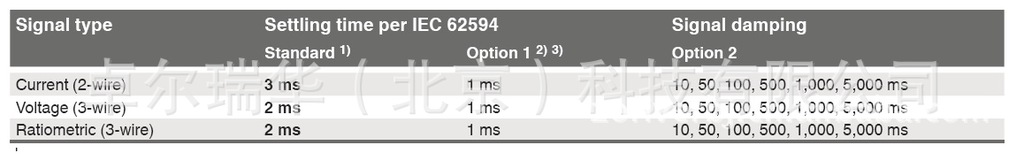

Time response  1) 3 dB limit frequency: 500 Hz2) 3 dB limit frequency: 1,000 Hz3) Alternative specifications for 4 ... 20 mA output signal: Load: ≤ (power supply - 11.5 V) / 0.023 A Power supply: DC 12 ... 36 V

1) 3 dB limit frequency: 500 Hz2) 3 dB limit frequency: 1,000 Hz3) Alternative specifications for 4 ... 20 mA output signal: Load: ≤ (power supply - 11.5 V) / 0.023 A Power supply: DC 12 ... 36 V

Switch-on time 150 ms

Switch-on drift 5 s (60 s with optional zero point adjustment 0.1 %)

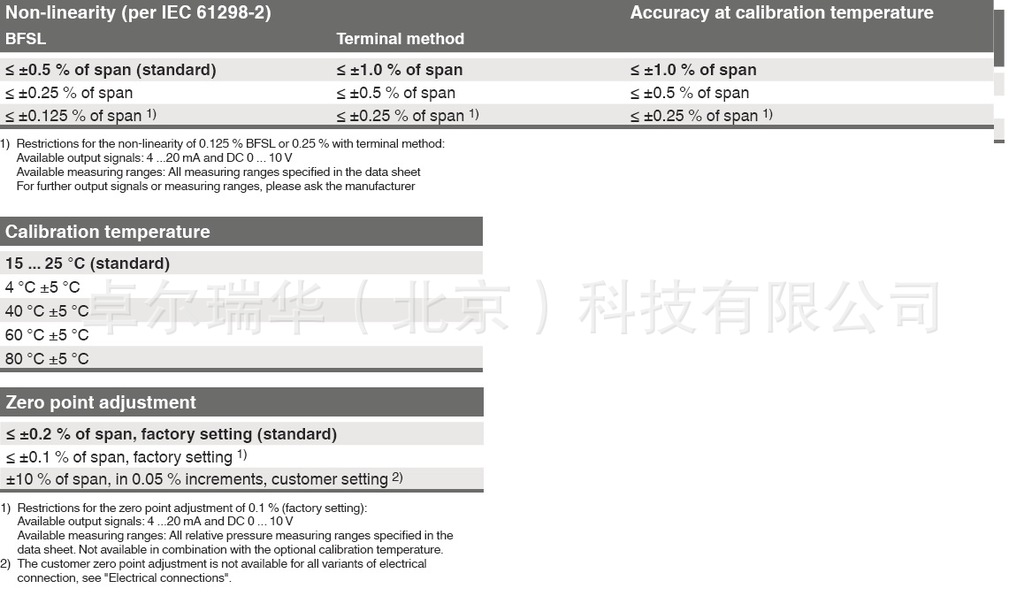

Accuracy data

Relationship to the mounting position For measuring ranges < 1 bar/15 psi, an additional zero offset of up to 0.15 %applies

Non-repeatability ≤ ±0.1 % of span

Temperature hysteresis 0.1 % of span at > 80 °C

Long-term drift (per IEC 61298-2) ≤ ±0.1 % of span ≤ ±0.2 % of span (with special measuring ranges)

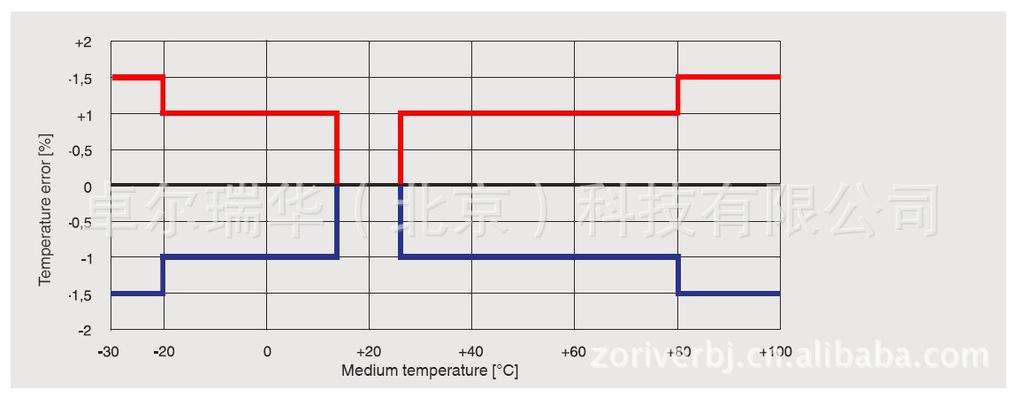

Temperature error (for calibration temperature of 15 ... 25 °C) For measuring ranges < 1 bar, special measuring ranges and instruments with an increased overpressure limit the respective temperature error increases by 0.5 % of span

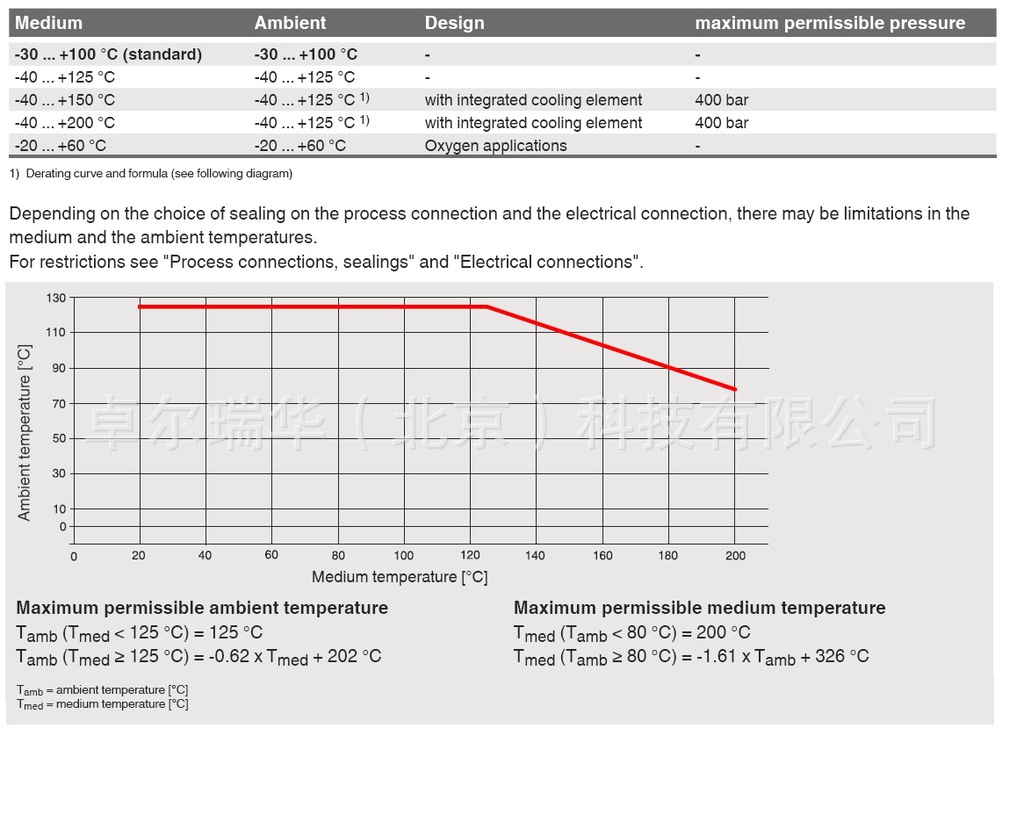

Operating conditions Permissible temperature ranges

Operating conditions Permissible temperature ranges

Storage and transport conditions Permissible temperature range: -40 ... +70 °C Maximum humidity (per IEC 68-2-78): 67 % r.h. at 40 °C (in accordance with 4K4H per EN 60721-3-4)

Storage and transport conditions Permissible temperature range: -40 ... +70 °C Maximum humidity (per IEC 68-2-78): 67 % r.h. at 40 °C (in accordance with 4K4H per EN 60721-3-4)

Climate class Storage: 1K3 (per EN 60721-3-1) Transport: 2K2 (per EN 60721-3-2) Operation: 4K4H (per EN 60721-3-4, without condensation or icing)

Vibration resistance (per IEC 68-2-6) 20 g, 10 ... 2,000 Hz, (40 g, 10 ... 2,000 Hz for heavy-duty connector) For instruments with cooling elements a limited vibration resistance applies 10 g (10 ... 2,000 Hz)

Continuous vibration resistance (per IEC 68-2-6) 10 g

Shock resistance (per IEC 68-2-27) 100 g, 6 ms (500 g, 1 ms for heavy-duty connector)

Service life 100 million load cycles (10 million load cycles for measuring ranges > 600 bar/7,500 psi)

Free-fall test (following IEC 60721-3-2) Individual packaging: 1.5 m Multiple packaging: 0.5 m PE bag: 0.5 m

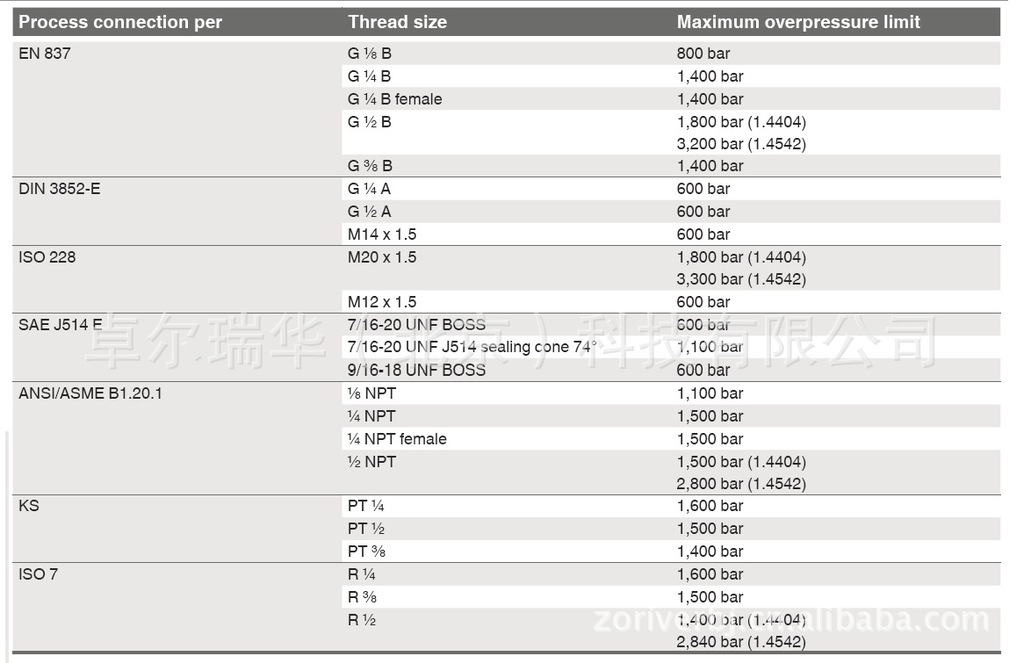

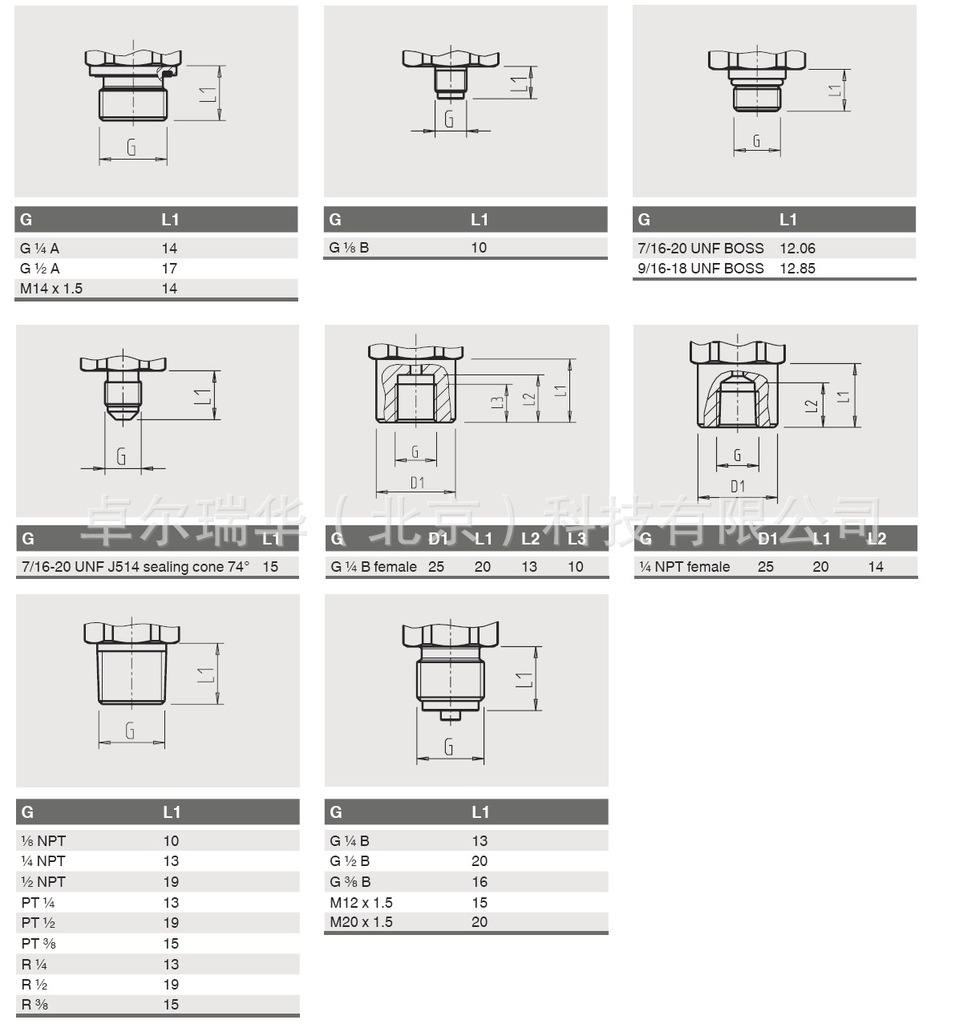

Process connections Available connections

Other process connections on request.

Other process connections on request.

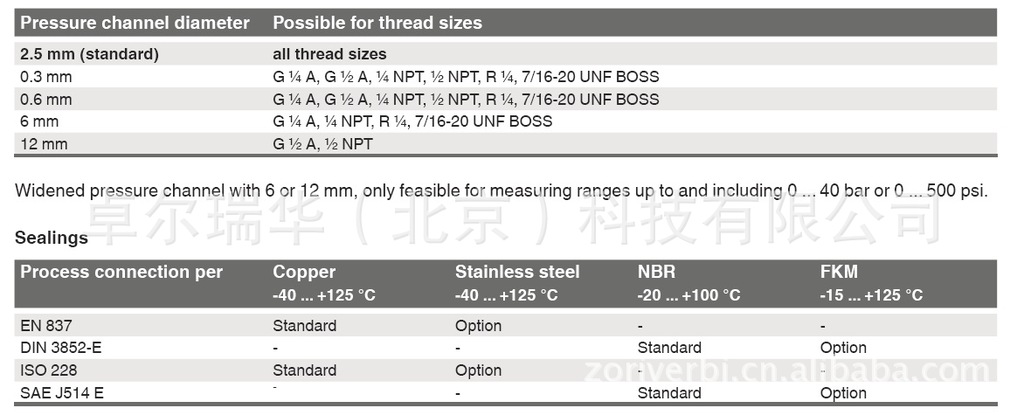

Process connections

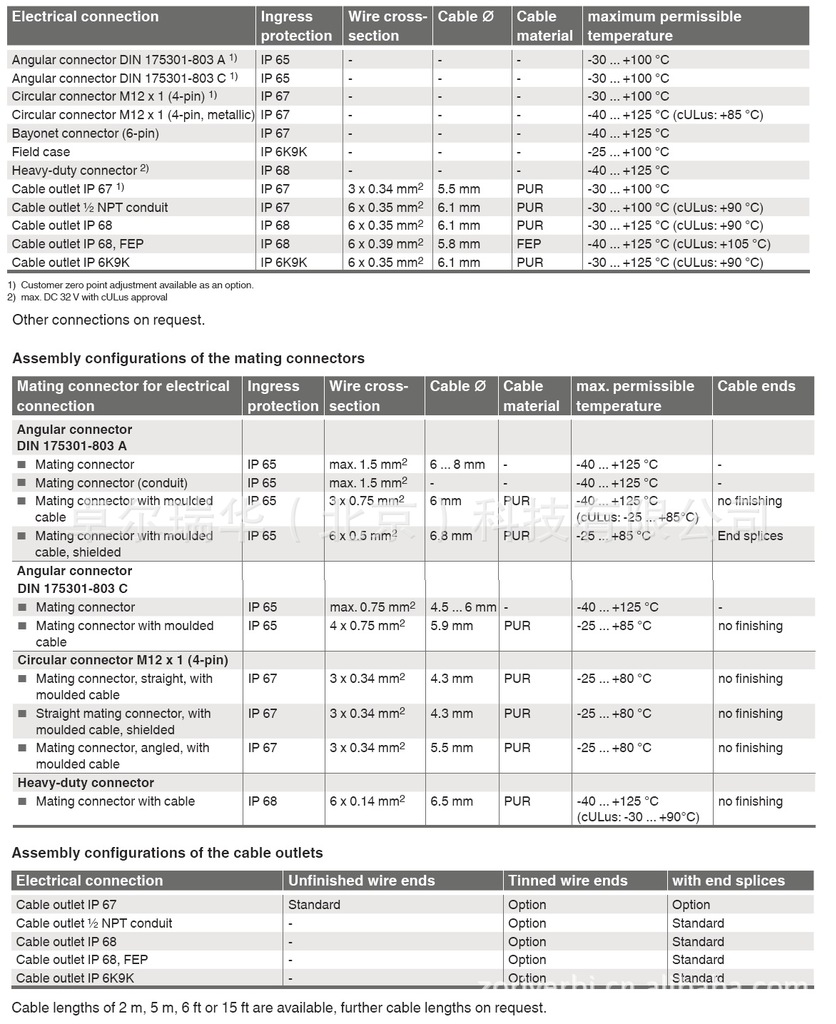

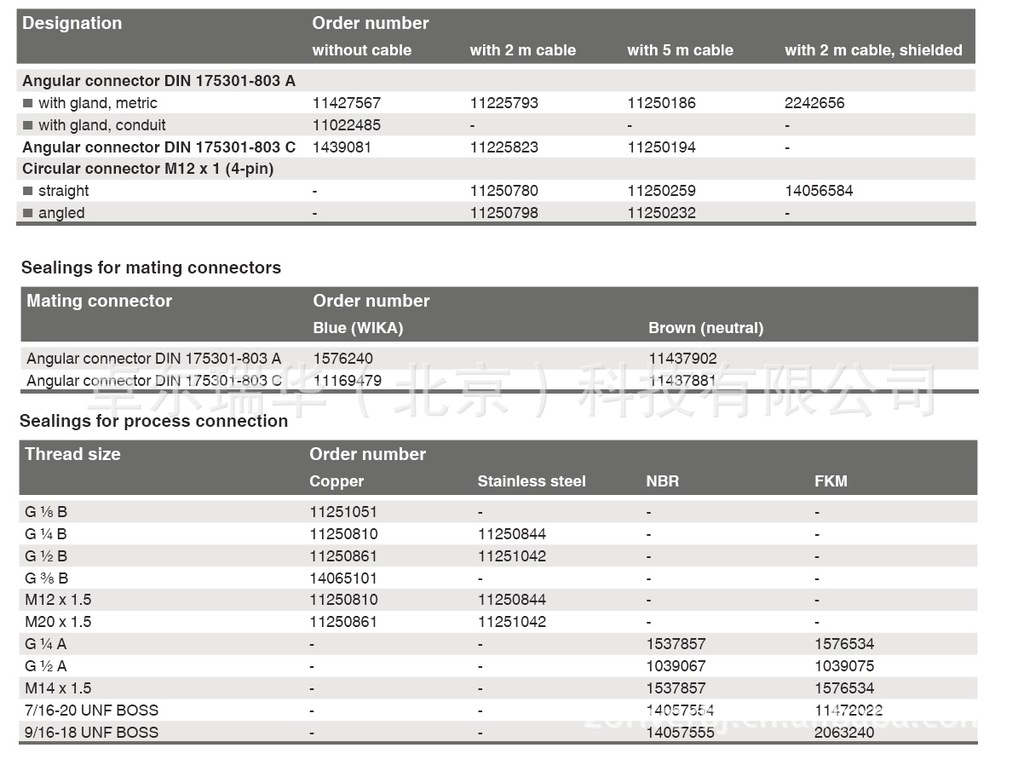

Electrical connections

Available connections

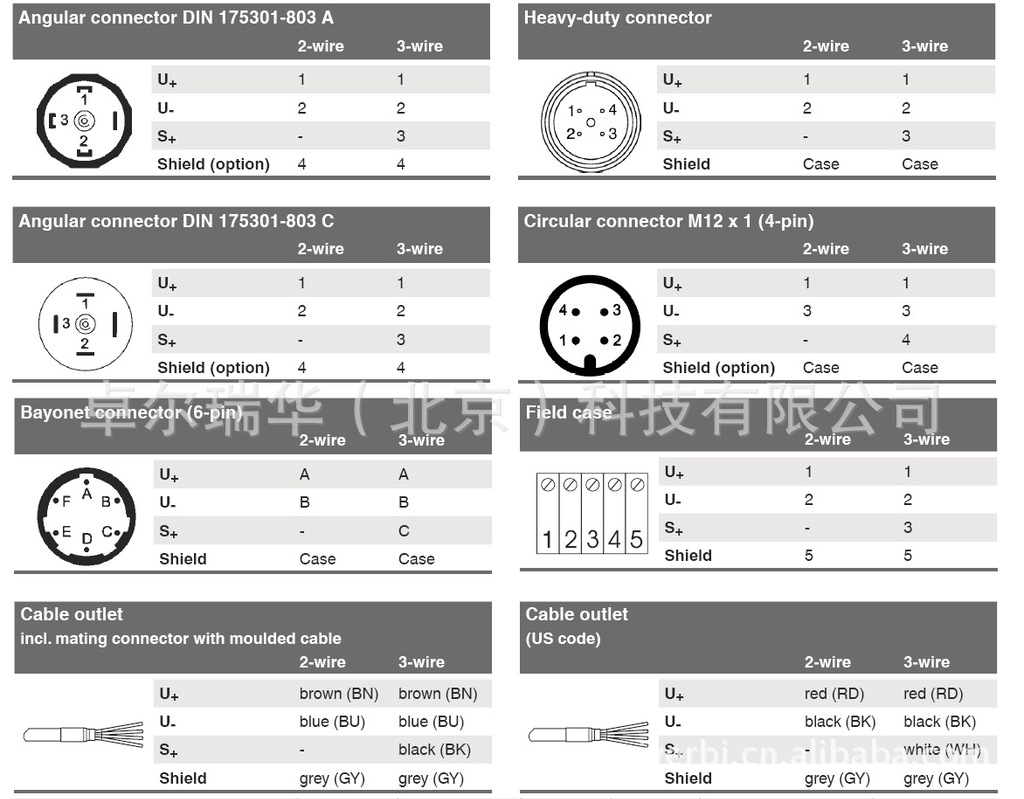

Connection diagrams

Connection diagrams

Other pin assignments on request.

Other pin assignments on request.

Electrical protective measures The electrical protective measures are not valid for ratiometric output signals. Short-circuit resistance: S+ vs. U- Reverse polarity protection: U+ vs. U- Resistance to overvoltage: DC 40 V Insulation voltage: DC 750 V

Materials

Wetted parts Relative measuring ranges: - Measuring ranges ≤ 10 bar/150 psi: 316L - Measuring ranges > 10 bar/150 psi: 316L + 13-8 PH Absolute pressure measuring ranges: - Measuring ranges ≤ 1,000 bar/10,000 psi: ASTM 630 and 13-8 PH - Measuring ranges > 1,000 bar/10,000 psi: 316L + 13-8 PH Sealing materials: see "Process connections"

Non-wetted parts Case: 316 Ti Zero point adjustment ring: PBT/PET GF30 Electrical connections: Angular connector DIN 175301-803 A: PBT/PET GF30 Angular connector DIN 175301-803 C: PBT/PET GF30 Circular connector M12 x 1 (4-pin): PBT/PET GF30 Circular connector M12 x 1 (4-pin, metallic): 316L Bayonet connector (6-pin) 316L + Al Field case: 316L, 316Ti Heavy-duty connector: 316L Cable outlet IP 67: PA66 Cable outlet ½ NPT conduit: 316L Cable outlet IP 68: 316L Cable outlet IP 68, FEP: 316L

Cable outlet IP 6K9K: 316L

Pressure transmission fluid Synthetic oil (for measuring ranges < 10 bar/150 psi relative and absolute pressure)

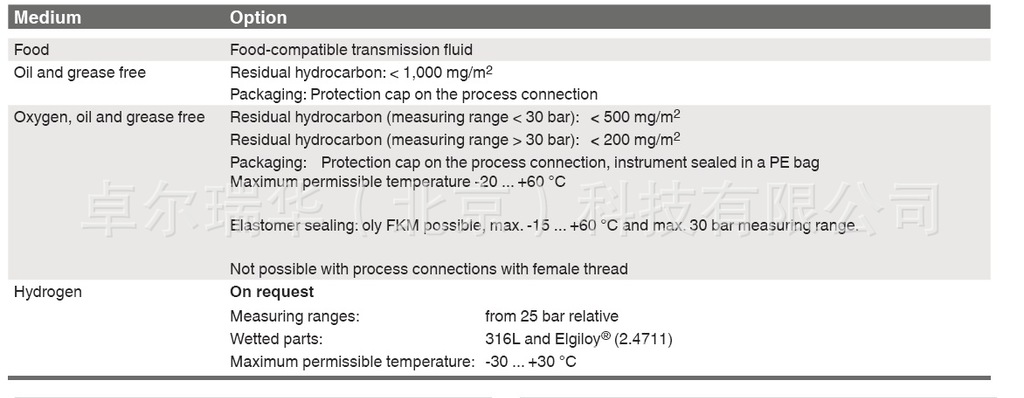

Options for specific media

CE conformity

CE conformity

Pressure equipment directive 97/23/EC

EMC directive 2004/108/EC, EN 61326 emission (group 1, class B) and interference immunity (industrial application)

EM field 30 V/m (80 ... 1,000 Mhz)

RoHS conformity Directive 2002/95/EC

Performance level (per EN ISO 13849-1:2008) Performance level: PL = C Category: Cat. = 1 Diagnostic coverage: DC = none MTTF: > 100 years

Certificates (option)

Available certificates 2.2 test report State-of-the-art manufacturing Wetted metallic parts Confirmation of the class and indication accuracy 3.1 inspection certificate Wetted metallic parts Wetted metallic parts with suppliers' certificate Confirmation of the class and indication accuracy List of single measured values DKD/DAkkS calibration certificate Certificates, see website

Scope of delivery

Test report Non-linearity 0.5 % 3 points Non-linearity 0.25 % 5 points Non-linearity 0.125 % 5 points

Packaging Individual packaging (standard) Multiple packaging (up to 20 pieces)

Instrument labelling WIKA label lasered (standard) Customer-specific label on request

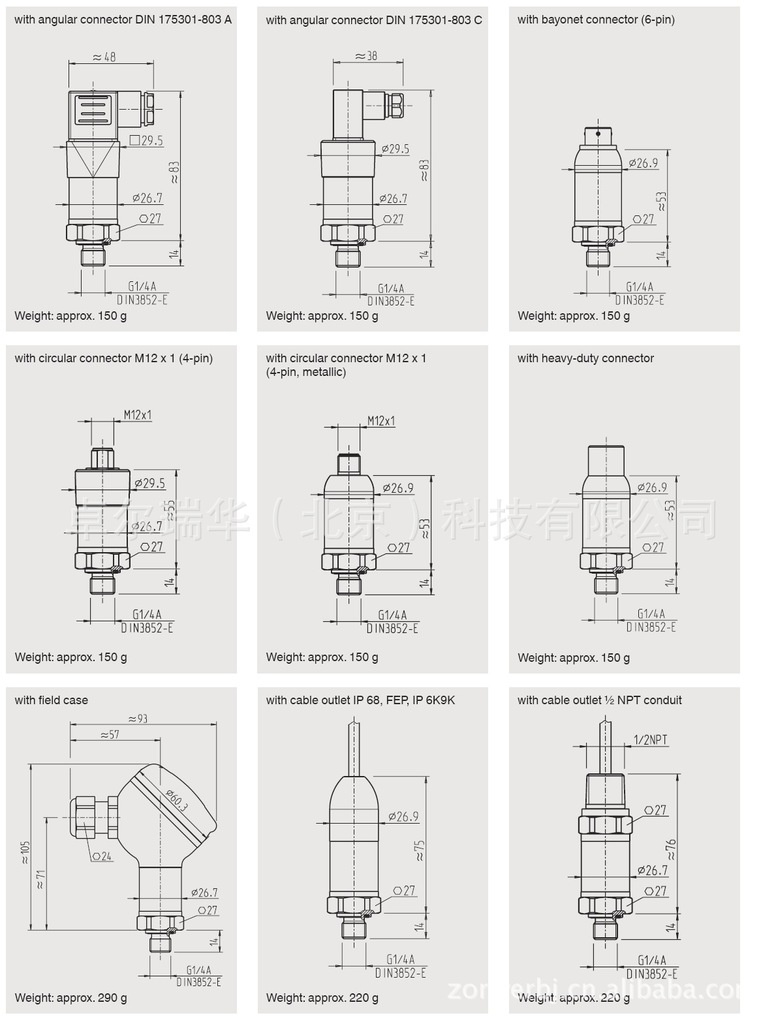

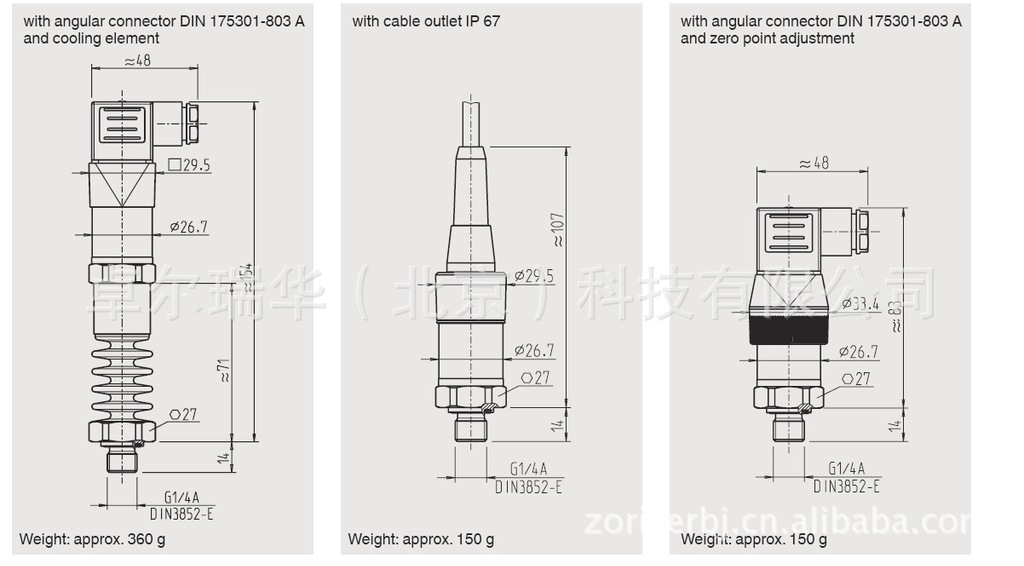

Dimensions in mm Pressure transmitter model S-20

Process connections

Process connections

Accessories and spare parts

Mating connector  Ordering information Model / Measuring range / Overpressure limit / Output signal / Non-linearity / Calibration temperature / Zero point adjustment/ Process connection / Pressure channel / Sealing / Electrical connection / Assembly / Cable length / Shielding / Certificates /Packaging / Instrument labelling / Accessories and spare parts

Ordering information Model / Measuring range / Overpressure limit / Output signal / Non-linearity / Calibration temperature / Zero point adjustment/ Process connection / Pressure channel / Sealing / Electrical connection / Assembly / Cable length / Shielding / Certificates /Packaging / Instrument labelling / Accessories and spare parts

欢迎致电咨询定购WIKA S-20 高精度 高压力范围 压力变送器 精度:0.125 1600bar

电话: 56291930 15910733293

传真:

QQ:823377546 1491421115 2636968574

邮箱:sales@zoriver.cn

公司官网:http://www.zoriver.cn http://www.zoriver.com.cn

FLWG山南高精度测量液体涡轮流量计使用方法

液体涡轮流量计FLWG液体涡轮流量计是吸取了国内外流量仪表先进技术经优化设计,具有结构简单、轻巧、精度高、复现性好、反应灵敏,安装维护使用方便等特点的新一代涡轮流量计。当被测流体流过传感器时,在流体作用下,叶轮受力旋转,其转速与管道平均流速成正比,叶轮的转动周期地改变磁电转换器的磁阻值。检测线圈中的磁通随之发生周期性变化,产生周期性的感应电势,即电脉冲信号,经放大器放大后,送至显示仪表显示。特点:【1】输出脉冲频率信号,适于总量计量计与计算机连接,无零点漂移,抗干扰能力强【2】可获得很高的频率信号(3-4KHz),信号分辨力强【3】范围度宽,中大口径可达1:20,小口径为1:10【4】结构紧凑轻巧,安装维护方便,流通能力大【5】专用型传感器类型多,可根据用户特殊需要设计为各类专用型传感器,例如低温型、双向型、井下型等【6】工作电源: A 外电源:+24VDC±15%,纹波≤±5%,适用于4-20mA输出、脉冲输出、RS485等 B 内电源:1组3.0V10AH锂电池,电池电压在2.0v-3.0v时均可正常工作【7】精度等级:1.0、1.5量程比:1:10;1:15;1:20

testo110高精度温度仪

testo110是一个高精度的温度仪。加上保护软套后使110使用于食品,实验室及冷藏/冷冻部门。它所用的技术是专为在冷藏室,橱柜及室外使用所设计的。 • 配件套装1 (用于不配保护软套的温度仪):多功能夹、挂绳和探头夹 • 配件套装2 (用于配有保护软套的温度仪):扣件、探头夹 • 单位切换:°C/°F • 食品 • 14mm字高显示、易于读取 • 低电量显示 • 保护软套,可放入洗碗机清洗 • 适用于冷藏过程中的测量 • 高精度温度仪带标定证书 • 精度高

测量食品储存温度 探头种类 量程精度实验室探头,可更换玻璃套管,耐腐蚀 -50…+150℃ 有撕拉带的管道探头,适用最大管径75mm -50…+70℃ 不锈钢高温食品探头,耐温+275°C,特氟龙电缆耐温+200°C (短时间内可达250°C) 0…275℃ 食品探头,不锈钢制造(IP67),特氟龙电缆耐温+200℃(短时间内可达+250℃) -50…+150℃ 冷冻食品探头,螺纹设计 -50…+140℃ 插入式食品探头,带特殊手柄,IP65,加强电缆(PUR),防烘烤 -50…+150℃ 食品探头(IP65),不锈钢制造,PUR电缆耐温+80℃,连接插头IP54 -50…+150℃ 防水表面探头,有扩大的测量尖端 -50…+150℃ 空气探头,用于检测仓储温度 -50…+150℃ 防水浸入/插入式探头 -50…+150℃ 技术数据显示 LCD 操作温度 0... +40 °C 存放温度 -20... +70 °C 电池种类 碱性电池9V 电池寿命 100 小时 尺寸 190x57x42 毫米 重量 300 克

保修 1 年

LX-3000Fykky牌分体式冷水机 高精度精美制冷机组

分体式冷水机主要应用原子吸收、激光器、真空镀膜机、离子刻蚀机、超低温实验仪器、氧氮分析仪、X射线衍射仪,液压源、油源等发热设备。由于实验室空间小,制冷机在工作的同时产生了大量的热量和噪音,为了给科技工作人员创造一个舒适安静的工作环境,分体式冷水机是很好的选择。联系人:136-0107-4786 技术参数:

* 温度范围:5~35℃;

* 控温精度:±0.1℃;

* 制 冷 量:20℃时3000W;

* 水箱容积:40L;

* 循环泵大压力:0~4.0Bar;

* 循环压力调节范围:1.5~3.6Bar;

* 循环泵大流量:0~45L/min;

* 仪器接口尺寸:1/2〞NPT

* 仪器室内机尺寸:W425×D750×H770mm

* 仪器室外机尺寸: W800×D270×H530mm

* 仪器重量: 56KG+45KG

主要特点:

* 温度、压力、水位均可显示;

* 业设计的动态控温系统,控温精度高,温度波动小;

* 简捷方便的人机操作界面,控制参数自动记忆;

* 各种制冷功率和循环泵压力,可满足各类仪器的冷却和恒温;

* 制冷系统关键部件采用进口名牌产品,工作稳定可靠;

* 多种循环泵可以选配,可选超静音、高压力或大流量;

* 循环压力可调,配不锈钢压力指示表;

* 标准不锈钢接口,可佩多种规格的接头和软管,外接闭路循环;

* 可选配加装RS485通讯,便于连接上位机;

* 可选停电恢复功能,可选流量报警;

G856F高精度智能磁力仪

本公司是专门研究生产G856F高精度智能磁力仪的专业公司,公司拥有多名多年生产同类仪器的专家。G856F是一种高精度的智能磁力仪,是多年生产同类仪器经验的结晶,是当今国际国内进的质子磁力仪,与G-856A和G-856AX兼容,其精度和稳定性优于G-856A和G-856AX;同时仪器线路板采用目前进的CAD设计,优化元器件布局和布线,采用独立的宽窗口LED显示板,的IDC接插件,的国外进口元件,仪器设有短路和电源接反等自动保护功能,配有RS232通信接口,可与USB接口相连输出数据,还可以外接电源,因此,仪器具有高稳定性,高性,使用非常方便。 仪器可配有外控实时传送接口,另加外控配件可实现数据与计算机的实时传送与控制,进行数字化采集。仪器内有程序控制开关,可以调节采样,仪器在磁赤道附近及高梯度地区正常工作,而其它类型的仪器只能勉强工作,并且不能取得的数据。

工作原理:G856F质子旋近磁力仪的原理是:根据质子在磁场中的旋进现象,因其旋进频率与磁场强度严格成正比,通过测量频率从而实现测量出磁场强度F仪器主要由探头和操作台(主机)组成。

技术参数:分辨力(灵敏度): 0.1 NT精 度: 0.5 NT(常温下)存储量: 5700个手动测量计数或12000个自动测量计数显示器: 6位LED显示及3位双排显示调谐范围: 25000--100000 NT梯度宽限: 4000 NT/M数据回放波特率: 110 至 9600 环境温度: -20度至50度机内时钟: 5秒/月(常温下)工作电压: DC 12 V采样时间: 4秒 至 999秒 可调机箱体积: 69 X 27 X 20 ( cm )主机重: 1.75Kg主机大小: 270 X 170 X 85(MM)输出: USB接口输出数据 (WINDOWS下回放,具有日变改正功能)

NA-42NA-42,NA42高精度大量程噪音分析仪-[Rion]日本理音

NA-42 高精度大量程噪音分析仪-[Rion]日本理音

NA-42,NA42高精度大量程噪音分析仪-[Rion]日本理音

【技术指标】 测量功能: 瞬时声级 Lp 、最大声级 Lmax 、波形峰值 Lpeak 。 频率范围: 1Hz ~ 100kHz 在 1Hz 约 -2dB ,在 100kHz 约 -3dB 频率计权: A 、 C 、 FLAT 线性范围:

麦克风 | 线性范围 | 频率范围 | JIS | IEC60651 |

UC-53A | 28 ~ 145dB | 10Hz ~ 20kHz | C1505 | TYPE1 |

UC-52 | 28 ~ 146dB | 20Hz ~ 8kHz | C1502 | TYPE2 |

UC-34P | 10 ~ 112dB | 10Hz ~ 12.5kHz | C1505 | TYPE1 |

UC-29 | 50 ~ 164dB | 20Hz ~ 100kHz | C1505 | TYPE1 |

UC-27 | 20 ~ 145dB | 5Hz ~ 12.5kHz | C1505 | TYPE1 |

UC-31 | 34 ~ 155dB | 10Hz ~ 35kHz | C1505 | TYPE1 |

NA-42,NA42高精度大量程噪音分析仪-[Rion]日本理音

背景噪音: A 计权: 1.5 μ Vrms 或更小、 C 计权: 1.5 μ Vrms 或更小 FLAT特性:7 μ Vrms或更小、 FLATHPF 20Hz,LPF 20kHz:2.5 μ Vrms或更小 时间计权: 快、慢,脉冲 RMS检测 :由数字处理 内置滤波器:高通 HPF : 3 阶 Butterworth 滤波器, 20Hz-3dB 低通 LPF : 3 阶 Butterworth 滤波器, 20kHz-3dB 标定:内部产生 1kHz 正弦信号 信号输出: AC、DC、串口RS232C 显示屏: 背光LCD 数字显示: 5位数字显示,显示范围70dB。 图 显示:显示量程 50dB或20dB,显 示周期0.1秒 电源: 4节干电池,连续操作可达14小时。AC适配器 环境条件: -10~50℃,10~90%RH 尺寸: 171H×120W×236Dmm。重量: 1.8千克

NA-42,NA42高精度大量程噪音分析仪-[Rion]日本理音

标准附件: • 电池四个• AC适配器一个 • 仪器箱一个 • 操作说明书一本

NA-42,NA42高精度大量程噪音分析仪-[Rion]日本理音

选购件:

• 麦克风 及电缆等 • 软件 • 声音标定

VT142高精度图像采集卡

| 主要特点: | ||||||

VT142使用新型PCI-E总线作为数据存取通道,使图像采集速度更快,是为适应计算机总线发展的新型图像采集卡,它是在DH-VT121的基础上扩展为四通道彩色视频采集卡,并基本消除了QP300在多路同时采集时存在的图像拉道的现象。同时DH-VT142为用户提供了自行加密的手段,可以保护用户知识产权不受侵犯。 | ||||||

高精度智能变送器

| 高精度智能变送器 | |

|

最新产品

- 晟思特录井压力变送器ST-LJ100系列 2025/11/22 17:14:19

- 晟思特录井压力变送器ST-LJ100系列 2025/11/22 17:12:59

- 晟思特泥浆压力变送器ST-P100系列 2025/11/22 17:09:38

- 晟思特泥浆压力变送器ST-P100系列 2025/11/22 17:08:22

- 晟思特泥浆压力变送器ST-P100系列 2025/11/22 17:06:46

- 晟思特油井高温压力变送器ST-RZB系列 2025/11/22 16:55:23

- 晟思特油井高温压力变送器ST-RZB系列 2025/11/22 16:51:43

- 晟思特油井高温压力变送器ST-RZB系列 2025/11/22 16:41:33

- 晟思特油井高温差压传感器ST-RC系列 2025/11/22 16:18:47

- 晟思特油井高温差压传感器ST-RC系列 2025/11/22 16:16:38

- 晟思特油井高温差压传感器ST-RC系列 2025/11/22 16:10:07

- 晟思特油井高温压力传感器ST-RC系列 2025/11/22 16:08:19

- 晟思特晟思特油井高温差压传感器ST-RC系列 2025/11/22 16:03:20

- 晟思特油井高温差压传感器ST-RC系列 2025/11/22 15:51:36

- 西安哪里租售黄疸仪 2025/11/22 15:46:46

- 晟思特油井高温压力传感器ST-RZ系列 2025/11/22 15:42:53

- 晟思特油井高温压力传感器ST-RY系列 2025/11/22 15:35:58

- 晟思特油井高温压力传感器ST-RY系列 2025/11/22 15:32:04

- 匹克球压缩力试验机 2025/11/22 15:05:51

- 匹克球反弹高度测量仪 2025/11/22 15:03:45

- ZY-1355PT匹克球反弹高度弹性系数测量仪 2025/11/22 15:00:36

- 混凝土碳化试验箱(卧式)(碳化20%-100%)厂家新升级 2025/11/22 14:57:04

- 混凝土碳化试验箱厂家新升级 2025/11/22 14:50:46

- maxseal进口电磁阀维修干货分享 2025/11/22 14:45:33

- KSB凯士比蝶阀维修基础讲解 2025/11/22 14:44:11

- 全自动碱骨料试验箱(全不锈钢)厂家新升级 2025/11/22 14:43:52

- 牧歌进口电磁阀维修基础讲解 2025/11/22 14:42:47

- TOMOE蝶阀关不动维修基础讲解 2025/11/22 14:41:37

- 萨姆森SAMSON蝶阀状态异常维修技术靠谱 2025/11/22 14:40:21

- HANK汉克蝶阀密封面泄漏维修亲测推荐 2025/11/22 14:38:46

SBC托利多传感器 称重显示仪表 托利多称重模块

SBC托利多传感器 称重显示仪表 托利多称重模块