KEM自动滴定仪AT-710系列

KEM自动滴定仪AT-710系列KEM自动滴定仪AT-710系列主要特点:AT-710M:触摸屏和操作单元之间无线连接,同时控制四台自动滴定测量单元。通过使用无线适配器(蓝牙),操作单元和滴定装置可以不用电缆连接。在测量样品过程中有危害性气体时,可将滴定装置放置在排烟柜中,由无线传输的操作单元执行滴定。AT-710M/AT-710S:滴定剂的信息存储在滴定管上的芯片中。即使滴定管单元转移到另一个滴定装置,也不需要重新输入滴定剂信息。AT-710M/AT-710S/AT-710B:滴定管单元特殊的开关阀门。减少滴定管和开关阀门间的死体积。特殊结构的设计可减少滴定剂的使用量和快速更换滴定单元。AT-710M/AT-710S/AT-710B:智能化电极电缆。电极的信息可透过电缆上传感器存储相关资料。电极校准的数据可应用到不同的自动滴定仪上。KEM自动滴定仪AT-710系列技术参数:

名称 | 自动电位滴定仪 | ||

仪器型号 | AT-710M | AT-710S | AT-710B |

仪器组成 | MCU-710M+AT-710+螺旋桨或磁力搅拌器 | MCU-710S+AT-710+螺旋桨或磁力搅拌器 | AT-710+螺旋桨或磁力搅拌器 |

测量范围 | 1)电位: -2000.0~2000.0mV2) pH: -20.000~20.000pH3)温度: 0~100°C | ||

滴定方式 | 自动滴定,自动间歇滴定,间歇滴定,恒pH滴定 | ||

石油中和值滴定,COD滴定 | |||

滴定类型 | 电位滴定(酸碱,氧化还原,沉淀),光度滴定,极化滴定,电导滴定 | ||

终点判断 | 全量滴定(自动终点),自动终点滴定,设定终点滴定 | ||

交叉点滴定,自动终点/设定终点滴定 | |||

特殊应用 | 量电极电位(pH, mV),酸解离常数(pKa) | ||

同时记录双通道电位,学习滴定 | |||

输入设置 | 触摸屏输入 | 按键输入 | |

显示 | 1) 8.4英寸彩色液晶屏,800x600点 | 1) LED背景光源液晶屏 | |

2)英文/日文/中文/韩文/俄文/西语/德语/法语 | 2)英文/日文/中文/韩文/俄文/西语 | ||

3)四个通道同时显示 | 3)一个通道显示 | 3)一个通道显示 | |

计算 | 浓度计算,统计计算(平均值,标准差,相对标准差),自动输入空白和滴定度 | ||

数据储存 | 500组样品结果 | 50组样品结果 | |

GLP认证 | 登记操作者/使用群组管理滴定剂:提示滴定度测量日期/指示滴定剂剩余量/提示滴定管活塞更换日期/提示滴定剂换日期/滴定度测量履历性能检查:提醒计划检查日期/记录检查结果电极管理:记录校正日期/记录校正履历/电极检查/电极检查履历滴定管验证:验证/记录验证结果时间管理:显示操作时间 | 登记操作者/记录检查结果/电极校正记录/滴定管精度确认/时间管理 | |

滴定管单元 | 20mL玻璃滴定管附褐色保护套(标配),选配: 10mL,5mL或1mL | ||

滴定管精确度 | 50mL滴定管(自动注入器): ±0.5mL20mL滴定管: 0.02mL 重复性: 0.01mL10mL滴定管: 0.015mL 重复性: 0.005mL5mL滴定管: 0.01mL 重复性: 0.003mL1mL滴定管: 0.005mL 重复性: 0.001mL | ||

扩大器 | 1) STD: pH(mV), mV,双通道(标配)2) PTA: pH(mV), mV,光度,三通道3) POA: pH(mV), mV,极化,三通道4) CMT: pH(mV), mV,电导,三通道5) TET: pH(mV),pH(mv), mV,三通道 | ||

外部输出 | RS-232C x3 | RS-232C x 2 | |

打印机,电子天平,数据软件(SOFT-CAP) | |||

USB x; 1 | USB x 1 | ||

U盘,热敏打印机,A4打印机,键盘, 条码机,脚踏开关, USB集线器 | U盘,热敏打印机,键盘,条码机,脚踏开关, USB集线器,安卓设备 | ||

LAN x 1 :电脑(PC) | |||

扩充功能 | 测量单元:电位滴定仪(AT-710)容量水分仪(MKV-710)库仑水分仪MKC-710)最多四台测量单元 | ||

自动活塞滴定管:最多可控制10台滴定管驱动单元(包括主机两台) | |||

多样品自动进样器: CHA-600,CHA-700 | CHA-700 | ||

使用环境 | 1)温度: 5~35°C2)相对湿度: 85%RH以下 | ||

电源 | AC100~240V,50Hz/60Hz | ||

耗电量 | 主机:约30瓦打印机:约7瓦 | 主机:约20瓦打印机:约7瓦 | |

尺寸 | 触摸屏: 225(W) x 190(D) x 42(H)mm | ||

滴定单元: 141(W) x 296(D) x 367(H)mm(不包括管路)打印机: 106(W) x 180(D) x 88(H)mm | |||

重量 | 触摸屏:约1.5公斤 | ||

滴定单元:约4.0公斤打印机:约0.4公斤 | |||

直销18米移动式输送机 DY4031移动式皮带输送机 全自动

新乡市百亿机械设备有限公司是一家以筛选设备、输送提升设备与矿山设备为主,集研发、制造、销售为一体的机械设备制造企业。产品包括各类筛选设备、三次元旋振筛、超声波振动筛、直线振动筛、摇摆筛、气流筛、圆振动筛、热矿振动筛、冷矿振动筛、概率筛、输送设备、提升设备、振动给料机、磨破设备。百亿机械可为用户提供项目设计,工艺流程设计,标准和非标准产品设计及制造。

公司名称:新乡市百亿机械设备有限公司

联系方式: 13353679328李经理

QQ:2787940889

地址:新乡市牧野区宏利大道西段东冀场工业园

网址:http://www.byjxzds.com/ www.byjxzds.com

一、 DY5051移动式皮带输送机概述移动式皮带输送机适用于粮食、轻工业、装车、化工、建材、码头、仓库、工地等输送散状物料或箱袋状物品,特别适合在化肥厂、水泥厂等需要人工装车的环境中使用,节省了大量人员,移动式皮带输送机稍加改装后也可以在餐饮、酿造、服装、电子等流水线作业中使用。二、DY5051移动式皮带输送机结构组成移动式皮带输送机由机身大架、行走轮、万向轮、升降装置等组成。其中机身大架普通情况下以钢管制作,以减轻自身重量,提高该皮带机的移动性和轻便型。升降装置为电动升降,减少人工升降带来的危险以及作业强度。三、DY5051移动式皮带输送机设备特点①、移动式皮带输送机适用场地不限,无论室内还是室外,均可以正常作业,尽量减少雨天作业。②、移动性能良好,正常情况下,一个成年男子进行移动没有任何问题。通过性好,可以直接进行装车作业,物料转运等场合,也可以适用物流装卸作业。③、操作方便,本机配有控制电箱,包含一个主控开关,一个升降开关。无需人工值守,开机即可作业。四、DY5051移动式皮带输送机维护事项①、尽量减少移动式皮带输送机在潮湿环境以及雨天作业,防止机身和部件长期接触水分而生锈损毁。②、定期检查输送带走向,保证输送带运行方向平稳,避免因输送带跑偏而产生不必要的损失。③、定期进行机身紧固件的检查,保证螺栓以及张紧装置的良好状态,及时添加润滑油,保证轴承的润滑,定期检查托辊及其他,更换损坏部件,保障皮带机的正常使用。

五、DY5051移动式皮带输送机型号及选用须知移动式皮带输送机带宽有500mm;600mm;800mm等。(如需不同带宽请提前告知)该型号皮带输送机长度有6米;8米;10米;12米以及15米及20米(20米需要特殊告知,机身结构架不同)如输送磨琢性较大的物料,请提前告知,具体长度和宽度以及产量有特殊要求的,可以特殊设计生产。

特别提醒:★任何来电/来函询查询有关输送机时,敬请一并提供下列资料,以便对贵方的查询做出迅速准确的回复★需处理原料:名称 粒度结构 比重 含水量 粘度 温度 等★使用现场的:输送长度、提升高度等其他★处理量:公斤/小时 公升/小时

【原创内容】非标准筛,又称非标准套筛,是现场对粒度大的物料(如原矿或各段破碎机的产物)进行粒度分析,而自行制造的套筛,它没有一定的标准,筛孔要求也不太严格,又多为手工操作,所以叫非标准筛或手筛。生产铝漆包线产品本身就是违反家政策的。同时,铝代铜只是企业应对高成本的一种应急手段,中小立式振动电机企业要增强抵抗原材料上涨风险的能力,归根结底还得要走科技创新、品牌立企的道路。直线振动筛采用双振动电机驱动,当两台振动电机做同步、反缶旋转时,其偏心块所产生的激振力在平行于电机轴线的方向相互抵消,在垂直于电机轴的方向叠为一合力,因此筛机的运动轨迹为一直线。其两电机轴相对筛面有一倾角,在激振力和物料自重力的合力作用下,物料在筛面上被抛起跳跃式向前作直线运动,从而达到对物料进行筛选和分级的目的。它的特点与工作原理:天和滚筒筛滚筒筛是由六角形滚筒、机架、漏斗、减速器、电动机五个部分成。破碎的石料进入滚筒后,一方面随着滚筒转动而被筛选,靠滚筒旋转的离心力及跳汰作用来筛分物料。一方面粒度大的石料沿着滚筒的斜度向前流动,通过不同网目的的筛网逐渐被筛出。对于粒度大于6mm的物料,筛析所用的筛子一般为非标准筛(手筛)。筛孔大小根据需要确定。一般为150、120、100、80、70、50、25、12、8、6、3mm等,由于它不是通用的,筛孔尺寸也没有统一规定,筛子的大小也各有不同,可以根据各现场的需要自行制造。直线振动筛可以选用全不锈钢直线振动筛是利用振动电机激振作为振动源,使物料在筛网上被抛起,同时向前作直线运动,物料从给料机均匀地进入筛分机的进料口,通过多层筛网产生数种规格的筛上物、筛下物、分别从各自的出口排出。非标准筛,又称非标准套筛,是现场对粒度大的物料(如原矿或各段破碎机的产物)进行粒度分析,而自行制造的套筛,它没有一定的标准,筛孔要求也不太严格,又多为手工操作,所以叫非标准筛或手筛。不大的石料筛出后落入各自的漏斗,然后由人工运出或自流送往成品堆。其结构简单可靠、运行平稳,具有密封好、无污染、噪音小、换网快捷、分级细、分选比例大、产量高、分选准确、故障率低、维修方便等优点,特别适用于砂石料场的分级使用。滚筒筛做工精细,

【原创内容】非标准筛,又称非标准套筛,是现场对粒度大的物料(如原矿或各段破碎机的产物)进行粒度分析,而自行制造的套筛,它没有一定的标准,筛孔要求也不太严格,又多为手工操作,所以叫非标准筛或手筛。生产铝漆包线产品本身就是违反家政策的。同时,铝代铜只是企业应对高成本的一种应急手段,中小立式振动电机企业要增强抵抗原材料上涨风险的能力,归根结底还得要走科技创新、品牌立企的道路。直线振动筛采用双振动电机驱动,当两台振动电机做同步、反缶旋转时,其偏心块所产生的激振力在平行于电机轴线的方向相互抵消,在垂直于电机轴的方向叠为一合力,因此筛机的运动轨迹为一直线。其两电机轴相对筛面有一倾角,在激振力和物料自重力的合力作用下,物料在筛面上被抛起跳跃式向前作直线运动,从而达到对物料进行筛选和分级的目的。它的特点与工作原理:天和滚筒筛滚筒筛是由六角形滚筒、机架、漏斗、减速器、电动机五个部分成。破碎的石料进入滚筒后,一方面随着滚筒转动而被筛选,靠滚筒旋转的离心力及跳汰作用来筛分物料。一方面粒度大的石料沿着滚筒的斜度向前流动,通过不同网目的的筛网逐渐被筛出。对于粒度大于6mm的物料,筛析所用的筛子一般为非标准筛(手筛)。筛孔大小根据需要确定。一般为150、120、100、80、70、50、25、12、8、6、3mm等,由于它不是通用的,筛孔尺寸也没有统一规定,筛子的大小也各有不同,可以根据各现场的需要自行制造。直线振动筛可以选用全不锈钢直线振动筛是利用振动电机激振作为振动源,使物料在筛网上被抛起,同时向前作直线运动,物料从给料机均匀地进入筛分机的进料口,通过多层筛网产生数种规格的筛上物、筛下物、分别从各自的出口排出。非标准筛,又称非标准套筛,是现场对粒度大的物料(如原矿或各段破碎机的产物)进行粒度分析,而自行制造的套筛,它没有一定的标准,筛孔要求也不太严格,又多为手工操作,所以叫非标准筛或手筛。不大的石料筛出后落入各自的漏斗,然后由人工运出或自流送往成品堆。其结构简单可靠、运行平稳,具有密封好、无污染、噪音小、换网快捷、分级细、分选比例大、产量高、分选准确、故障率低、维修方便等优点,特别适用于砂石料场的分级使用。滚筒筛做工精细,

西门子6XV1830-0EH10通讯电缆

产品名称:西门子6XV1830-0EH10通讯电缆,西门子电缆,西门子DP电缆,西门子PROFIBUS通讯电缆,西门子电缆订购型号:6XV1830-0EH10,屏蔽的双绞电缆

产品定货号

西门子通讯电缆 6XV1830-0EH10

Profibus DP 电缆 6XV1830-0EH10

ProfibusDP软电缆 6XV1830-3EH10

Profibus PA 电缆 6XV1830-5FH10 6XV1830-5EH10

工业以太网电缆 6XV1850-0AH10

Profibus 电缆 6XV1840-2AH10

Profibus DP 电缆 采用实心裸铜线导体作芯线,加厚铝箔和加密裸金属丝编织层,屏蔽效果好,紫色PVC外护套。具有良好的信号传输性能。

6XV1830-0EH10 L2电缆 2芯屏蔽(PROFIBUS总线电缆)

其他产品介绍:

网卡及电缆 6ES7 972-0CB20-0XA0 USB接口编程适配器(USB接口编程电缆)6ES7 901-3CB30-0XA0 编程/通讯电缆,PC/PPI,带光电隔离,5-开关,5m6ES7 901-3DB30-0XA0 编程/通讯电缆,PC/PPI,带光电隔离,USB接口,5-开关

6ES7 972-0CB35-0XA0 TS适配器II 用于调制解调器远程服务6ES7 972-0CC35-0XA0 TS适配器II 用于ISDN 远程服务6GK1 561-1AA01 CP5611网卡(PCI总线软卡,支持MPI,PPI,PROFIBUS-DP)6GK1 551-2AA00 CP5512网卡(PCMCIA总线软卡,支持MPI,PPI,PROFIBUS-DP,笔记本电脑用,32BIT)6GK1 561-3AA01 CP5613网卡(PCI总线硬卡,支持PROFIBUS-DP主站)6GK1 561-3FA00 CP5613光纤网卡(PCI总线硬卡,支持PROFIBUS-DP主站6GK1 561-4AA01 CP5614网卡(PCI总线硬卡,支持PROFIBUS-DP主站/从站)6GK1 561-4FA00 CP5614光纤网卡(PCI总线硬卡,支持PROFIBUS-DP主站/从站)6XV1 830-0EH10 PROFIBUS通讯电缆6XV1 820-5AH10 光纤电缆(米)6XV1 820-5BH50 光纤电缆 含BFOC (5米)6XV1 820-5BT10 光纤电缆 含BFOC (100米)6GK1 901-0DA20-0AA0 BFOC接头(每包20只)6ES7 901-0BF00-0AA0 5米MPI电缆6ES7 901-1BF00-0XA0 RS232电缆总线连接器 6GK1 905-6AA00 快速剥线工具6ES7 972-0BA50-0XA0 快速连线网络接头(不带编程口)6ES7 972-0BB50-0XA0 快速连线网络接头(带编程口)6ES7 972-0BA12-0XA0 90度网络接头(不带编程口)6ES7 972-0BB12-0XA0 90度网络接头(带编程口)6ES7 972-0BA41-0XA0 35度网络接头(不带编程口)6ES7 972-0BB41-0XA0 35度网络接头(带编程口)6GK1 500-0EA02 无角度网络接头(不带编程口)6GK1 500-0FC00 无角度快速连线网络接头(不带编程口) 西门子CP5711网卡 订货号:6GK1571-1AA00

Siemens 适配器 6ES7972-0CB20-0XA0

Siemens 适配器 6ES7972-0CB20-0XA0 国产Siemens 适配器 6ES7901-3DB30-0XA0Siemens 适配器 6ES7901-3DB30-0XA0 国产

Siemens 电机 1FT6064-1AF71-3AG1Siemens 电源 6EP1 436-1SH01这型号停产了替代型号是 6EP1436-3BA00Siemens 开关电源 6EP1-1SH01 //请确认是否为:6EP1331-1SH01 //已升级为:6EP1331-1SH02Siemens 开关电源 或:6EP1437-1SH01Siemens 变频器 6SE7018-0EA61Siemens 数控 6FC5500-0AA11-1AA0Siemens 监控模块 6SN1145-1BA01-0BA1已停产,替代型号为:6SN1145-1BA01-0BA2

Siemens 通讯卡 6GK1161-3AA01

Siemens 4路模拟量输出模块 6ES7332-5HD01-0AB0Siemens 电源模块 6ES7307-1EA00-0AA0Siemens 模拟量输入模块 6ES7331-7KF02-0AB0Siemens 模块 6ES7153-1AA03-0XB0Siemens 通信处理器 6GK7443-5DX04-0XE0Siemens 通信处理器 6GK7443-1EX11-0XE0

Siemens 数字量输出模块 6ES7322-1BL00-0AA0Siemens 数字量输入模块 6ES7321-1BL00-0AA0Siemens FM计数器功能模块 6ES7350-2AH00-0AE0Siemens 存储器卡 6ES7952-1AL00-0AA0Siemens 位置输入模块 6ES7338-4BC01-0AB0Siemens 模拟量输出模块 6ES7332-5HF00-0AB1//请确认是否为:6ES7332-5HF00-0AB0Siemens 接口模块 6ES7158-0AD0A-0XA0 //请确认是否为: 6ES7158-0AD01-0XA0Siemens 电源模块 6ES7407-0KR02-0AA0

SIEMENS 电气件 A5E00166828SSIEMENS 软启动器 3RW4453-6BC44SIEMENS 伺服模块 6FX2003-0DA00

SIEMENS 模拟量输出模块 8路 332-5HF00-0AB0确认是否为:6ES7332-5HF00-0AB0SIEMENS 数字量输出模块 16路 332-1BH02-0AA0 确认是否为:6ES7321-1BH02-0AA0SIEMENS 数字量输入模块 16路 321-1BH02-0AA0 确认是否为:6ES7321-1BH02-0AA0SIEMENS DI模块 223-IPL22-0XA8确认是否为:6ES7223-1PL22-0XA8SIEMENS 插座开关 6FC5203-0AD10-0AA0 //已停产,替代型号为:6FC5203-0AF22-0AA2

SIEMENS 总线连接器 6ES7972-0BB12-0XA0 双头SIEMENS PLC PLC-CN226//请确认为:6ES7216-2BD22-0XB0SIEMENS PLC PLC-CN226//请确认为:6ES7216-2AD22-0XB0SIEMENS PLC 6ES7901-3CB30-0XA0SIEMENS 电缆线 6FX8002-2CA34-1AF0SIEMENS 电缆线 6FX8002-5DA05-1AF0SIEMENS 电缆线 6FX8002-2CA34-1AG0SIEMENS 电缆线 6FX8002-5DA05-1AG0SIEMENS PLC 6EW1380-1AB //已停产,替代型号为:6EP1332-1SH22SIEMENS 模块 6ED1055-1FB10-0BA0SIEMENS 交流伺服电机 1FT6082-1AF71-4AG1SIEMENS 控制模块 6SN1118-0DM31-0AA1 //已升级为:6SN1118-0DM31-0AA2SIEMENS NUC盒 6FC5247-0AA00-0AA3

SIEMENS 开关电源 6EP1436-3BA00

SIEMENS 变频器 6SE644-02UD33-0EA1SIEMENS 计数器模块 6ES7350-1AH03-0AE0

SIEMENS PLC模块 6ES7952-1KK0-0AA0(1M) SIEMENS 总接线连接器 6ES7972-0BA41-0XA0SIEMENS 总接线连接器 6ES7972-0BB41-0XA0

SIEMENS 数控备件 6FC9320-5DB010SIEMENS 变频器 6SL3040-0LA00-0AA1SIEMENS 伺服电机 1FT6084-8SF71-2UA1

SIEMENS 电缆线 6FX5002-5CG31-1DA0 15米SIEMENS 电缆线 6FX5002-2DC00-1DA0 15米SIEMENS 变频器 6SL3054-0AA01-1AA0 //已停产,替代型号为:6SL3054-0CG01-1AA0

SIEMENS 温度变速器 7NG3214-0NN00SIEMENS 直流调速器 6RA7075-6DS22-0SIEMENS 变频器 6SE7027-2TD61-ZSIEMENS 变频器 6SE7022-6TC61-ZSIEMENS 变频器 6SE7021-3TB61-ZSIEMENS 变频器 6SE7032-7ES87-2DC0SIEMENS 变频器 6SE7021-0TA61-ZL33SIEMENS 变频器 6SE6400-3CC00-2AD3

SIEMENS PLC 6ES7307-1EA00-0AA0 ps307 5A DC24VSIEMENS PLC 6ES7315-2AG10-0AB0 cpu315-2dpSIEMENS PLC 6ES7343-1EX21-0XE0 cpu343-1 //已升级为:6ES7343-1EX30-0XE0SIEMENS PLC按线端子 6ES7321-1BL00-0AA0 SM321 DI32XDC24VSIEMENS 变频器 6SE6440-2UD27-5CA1 MICROMASTER440SIEMENS 变频器 6SE6440-2UD22-2BA1 MICROMASTER440 SIEMENS 变频器 6SE6440-2UD21-5AA1 MICROMASTER440

SIEMENS 操作面板 6FC5203-0AD10-0AA0 //已停产,替代型号为:6FC5203-0AF22-0AA2SIEMENS 电源模块 6SN1145-1BA01-0BA2

SIEMENS 过滤器 6EW1811-8AA SIEMENS 电容器 6SY7000-0AA52 2.5UF 400VSIEMENS 电容器 6SY7000-0AB10 4UF 400VSIEMENS 电源模块 6ES7153-1AA03-0XB0 ET200 M+

SIEMENS 变频器 6AU1230-2AA01-0AA0SIEMENS 伺服电机 1FT6084-8AF71-4UA4

SIEMENS 传感器 7ME6520-6PB13-2AA1-ZY17C14SIEMENS 传感器 7ME6920-1QA10-1AA0

SIEMENS 电气件 A5E00836867SIEMENS 超声波开关 7ML1510-3HA04SIEMENS 超声波开关 7ML1930-1ACSIEMENS 超声波开关 7ML1830-1BTSIEMENS 超声波开关 7ML1141-0KE30-ZY15 Y15=LT-02SIEMENS 超声波开关 7ML5004-1AA10-1A-ZY15SIEMENS 超声波开关 7ML1830-2ANSIEMENS 超声波开关 7ML1830-1BPSIEMENS 超声波开关 7ML1998-5BP61SIEMENS 压力变送器 7MF4033-1DY10-1AB7-Z C11+C12+D12+Y01+Y21 Y01=0-7Bar Y21=Bar Y15=DPT-01SIEMENS 压力变送器 7MF4910-2AA01-ZC11C12V01SIEMENS 超声波开关 7ML1002-0AA05SIEMENS 超声波开关 7ML1106-1BA20-0ASIEMENS 超声波开关 7ML1830-1BNSIEMENS 超声波开关 7ML1830-2AASIEMENS 超声波开关 7ML1812-3AA1

SIEMENS 超声波流量计 7ME3210-2TA11-2PB0SIEMENS 超声波流量计 7ME3210-3TA11-2PB0SIEMENS 超声波流量计 7ME3210-4FA11-2PB0SIEMENS 可编程控制器 6ES7331-7KF02-0AB0SIEMENS 可编程控制器 6ES7634-1DF02-0AE3SIEMENS 元器件 RVA:96601831

SIEMENS 离散信号输入模块 6ES7321-1BL00-0AA0SIEMENS 离散信号输入模块 6ES7321-1BL00-0AA0SIEMENS 适配器 6ES3190-0XX87-8PB0SIEMENS PCU50电源 A5E00100846

SIEMENS 编码器 7ML5830-2AJ

SIEMENS 操作面板 6ES7626-1DG04-0AE3SIEMENS 驱动模块 6SN1118-0DJ23-0AA1 //已停产,替代型号为:6SN1118-0DJ23-0AA2SIEMENS 驱动模块 6SN1123-1AA01-0FA1SIEMENS NCU-BOX 6FC5247-0AA00-0AA3SIEMENS 电源模块 6SN1145-1BB00-0FA1SIEMENS 驱动模块 6SN1123-1AA00-0EA2SIEMENS 驱动模块 6SN1123-1AB00-0BA1SIEMENS UEB模块 6SN1112-1AC01-0AA1SIEMENS 测量模块 6SN1118-0NJ01-0AA1SIEMENS NCU模块 6FC5357-0BB25-0AA0SIEMENS 功率模块 6SN1123-1AA00-0JA1SIEMENS 功率模块 6SN1123-1AA00-0LA1 //已停产,替代型号为:6SN1123-1AA00-0LA3SIEMENS 功率模块 6SN1123-1AA00-0KA1SIEMENS 测量模块 6SN1118-0DM31-0AA1//已停产,替代型号为:6SN1118-0DM31-0AA2SIEMENS 编码器 EWN:8399501415000SIEMENS 变频器 6SE7024-7TD61-Z

SIEMENS 电气阀门定位器 6DR5020-0NG00-0AA0

SIEMENS DI模块 6ES7138-4FA03-0AB0 4/8F-DI(PR0FIsafe) //已升级为:6ES7138-4FA04-0AB0SIEMENS DO模块 6ES7138-4FB02-0AB0 4F-D0 //已升级为:6ES7138-4FB03-0AB0SIEMENS 电机 1FK7101-5AF71-1AG0 4F-D0SIEMENS 伺服电机 1FK7022-5AK71-7TG0 0.85 Nm n max=6000SIEMENS 伺服电机 1FK7080-5AF71-1EG0SIEMENS 电缆 6FX5002-2CF02-2BA0 110m 带接头(电机和控制器SIEMENS 电缆 6FX5002-5CA01-1JA0 80m 带接头(电机和控制器)SIEMENS 电缆 6FX5002-5CA31-1GA0 60m 带接头(电机和控制器)SIEMENS 电缆 6FX5002-5DA01-2BA0 110m 带接头(电机和控制器)SIEMENS 电缆 6FX5002-5DA61-2AA0 100m 带接头(电机和控制器)SIEMENS 进线滤波器 6SN1111-0AA01-1AA1SIEMENS 扩展接口模块 6ES7153-2BA02-0XB0 ET200M/

SIEMENS 变频器 6SL3760-0DC00-0AA0SIEMENS 变频器 6SL3760-0DD00-0AA0SIEMENS 备件 RVA:010650302

SIEMENS 脱硫PLC模块 6ES7291-8BA20-OXAOSIEMENS 脱硫PLC模块 6ES7272-0AA30-0YA1SIEMENS 脱硫PLC模块 6ES7331-7KF02-0AB0SIEMENS 脱硫PLC模块 6ES7332-5HF00-0AB0SIEMENS 脱硫PLC模块 "6ES7343-1EX30-0XEP//标准型号为:6GK7343-1EX30-0XE0"SIEMENS 脱硫PLC模块 6ES7222-1BF22-OXAO SIEMENS 脱硫PLC模块 6ES7231-OHC22-OXAO SIEMENS 脱硫PLC模块 6ES7232-OHB22-OXAO SIEMENS 脱硫PLC模块 6ES7216-2AD23-OXBO

SIEMENS 电源模块 6EP1332-2BA10SIEMENS 接口模块 6ES7151-1AB02-0AB0SIEMENS 供电模块 6ES7138-4CA01-0AA0SIEMENS 模拎量模块 6ES7134-4FB01-0AB0SIEMENS 输入模块 6ES131-4BD01-0AA0SIEMENS 输出模块 6ES132-4BD01-0AA0SIEMENS 端子模块 6ES7193-4CD30-0AA0SIEMENS 端子模块 6ES7193-4CB30-0AA0SIEMENS 辅件 6GK1901-0FB00-0AA0SIEMENS 压力变送器 7MF1564-3BG01-1AA1

SIEMENS 接口模块 6SE7041-8HK85-1HA0SIEMENS 编码接口板 6SE7090-0XX84-3DB1SIEMENS 模块 6SE7038-6GL84-1JB0SIEMENS 电源模块 PS407 10ASIEMENS 接口模块 6ES7153-2BAO2-OXBO

SIEMENS 输入模块 6ES7231-0HC22-0XA0SIEMENS 适配器 6ES7277-0AA22-0XA0SSIEMENS 模块 6AR1302-0AF00-0AA0SIEMENS 模块 6AR1302-0AE00-0AA0SIEMENS 模块 6ES7211-0AA23-0XB0SIEMENS 模块 6ES7211-0BA23-0XB0SIEMENS 适配器 "6ES7972-OBA11-0XA0 升级型号6ES7972-0BA12-0XA0"SIEMENS 传感器 6GT2600-0AA00已停产代替型号为6GT2600-0AA10SIEMENS 电机 1FT6064-6AF71-4FG2SIEMENS PLC模块 6ES7953-8LJ11-0AA0升级型号6ES7953-8LJ20-0AA0SIEMENS 触摸屏 6AV6643-0CD01-1AX1SIEMENS 电源 6ES7307-1EA00-0AA0SIEMENS 数字输入模块 6ES7321-1BL00-0AA0SIEMENS 数字输出模块了 6ES7322-1BL00-0AA0SIEMENS MMC 6ES7953-8LJ20-0AA0SIEMENS 前连接器 6ES7392-1AM00-0AA0SIEMENS PC适配器 6ES7972-0CB20-0XA0SIEMENS 网络连接器 6ES7972-0BA50-0XA0SIEMENS 网络连接器带编程口 6ES7972-0BB50-0XA0SIEMENS 网络连接器带编程口 6ES7214-1BD23-0XB0

SIEMENS 适配器 6ES7274-1XH00-0XA0SIEMENS 软启动器 3RW4436-6BC44SIEMENS PLC模块 6ES7313-6CF03-0AB0SIEMENS PLC模块 6ES7354-1AH01-0AE0SIEMENS PLC模块 6ES7 214-1AD23-0XB8SIEMENS PLC模块 6SE7216-2BD23-0XB8

SIEMENS 变频器显示面板 6SE6400-0BP00-0AA0SIEMENS CBP2 6SE7090-0XX84-0FF5SIEMENS 功率接口板 6SE7041-8EK85-0HA0SIEMENS 接口板 6SE6400-1PB00-0AA0SIEMENS CBP2通讯模块 6SX7010-0FF05SIEMENS CUVC模板 6SE7090-0XX84-0AB0SIEMENS SE25模板 6SD2280-0AA1SIEMENS 模板 6SE7 031-6FG84-1JC2停产无替代SIEMENS 接口背板 6SE7090-0XX84-1CE0SIEMENS SCB2通讯板 6SE7090-0XX84-0BD1SIEMENS 模块 6SE322-1HH01-0AE0 确认是否6ES7322-1HH01-0AA0SIEMENS 模块 6SE350-1AH03-0AE0 确认是否 6ES7350-1AH03-0AE0SIEMENS 通讯模块 6SL3040-0MA00-0AA1SIEMENS 通讯板 6SE7090-0XX84-0FJ0SIEMENS 整流单元 6SE7041-0EH85-0AA0

SIEMENS 变频器 6SE6440-2UD32-2DA1SIEMENS 模块 6ES7144-1FB31-0XB0 SIEMENS PLC模块 6ES7144-1GB41-0XB0 SIEMENS PLC模块 6ES7144-1JB31-0XB0 SIEMENS PLC模块 6ES7145-1GB31-0XB0 SIEMENS PLC模块 6ES7141-1BF12-0XB0 SIEMENS CPU模块 6ES7216-2AD22-0XB0SIEMENS CPU模块 6GK7343-1EX10-0XE0SIEMENS CPU模块 6ES7216-2BD23-0XB0SIEMENS PLC模块 6ES7145-4FF00-0AB0SIEMENS PLC模块 6ES7144-4GF00-0AB0SIEMENS PLC模块 6ES7194-4CB00-0AA0SIEMENS PLC模块 6ES7144-4JF00-0AB0SIEMENS PLC模块 6ES7194-4CA00-0AA0

SIEMENS 驱动控制板 6SN1118-0DK23-0AA1 //已升级为:6SN1118-0DK23-0AA2SIEMENS AI模块8点 6ES7331-7KF02-0AB0SIEMENS PLC模块 6ES7321-1BH02-0AA0SIEMENS DO模块16点 "6ES7332-1BH01-0AA0 //请确认是否为:6ES7322-1BH01-0AA0SIEMENS 模块 6ES7153-1AA03-0XB0SIEMENS 适配器 6ES7972-0BA52-0XA0SIEMENS 适配器 6ES7390-1AE80-0AA0SIEMENS 模块 6ES7390-5AA00-0AA0SIEMENS 模块 6ES7321-1BL00-0AA0SIEMENS 模块 6ES7392-1BM01-0AA0SIEMENS 模块 6ES7322-1BL00-0AA0SIEMENS 模块 6ES7331-7KF02-0AB0SIEMENS 模块 6ES7392-1BJ00-0AA0SIEMENS 模块 6ES7331-7PF01-0AB0SIEMENS 模块 6ES7332-5HD01-0AB0SIEMENS 模块 6ES7151-1CA00-3BL0SIEMENS 模块 6ES7193-4DL00-0AA0SIEMENS 模块 6ES7193-4FL00-0AA0SIEMENS 电源 6EP1935-6ME21SIEMENS 软启动器 3RW4445-6BC44

SIEMENS 变频器 6SE3111-5CA70-0BB0停产,建议型号6SE6440-2UC12-5AA1SIEMENS 超声波物位开关 7ML5007-1AA00-2ASIEMENS 伺服电源模块 6SN1123-1AA00-0AA1

SIEMENS 可编程控制器 6ES7 313-6CF03-0AB0SIEMENS 电源模块 6ES7 307-1EA00-0AA0SIEMENS 安装机架 6ES7 390-1AE80-0AA0SIEMENS 数字量扩展模块 6AG1323-1BH01-0AA0 //请确认是否为:6AG1323-1BH01-2AA0SIEMENS 模拟量扩展模块 6ES7331-1KF01-0AB0SIEMENS 模拟量扩展模块 6ES7332-5HF00-0AB0SIEMENS 通讯扩展模块 6ES7340-1CH00-0AE0SIEMENS 前连接器 6ES7392-1AJ00-0AA0SIEMENS 前连接器 6ES7392-1AM00-0AA0SIEMENS 控制器 6ES5-95-8MB04请确认是否为:6ES5095-8MB04SIEMENS PLC 6ES5262-8MA13

SIEMENS PLC 请确认是否为:6ES7197-1LB00-0XA0SIEMENS PLC 请确认是否为:6ES7417-4HL01-0AB0SIEMENS CPU模块 6ES7315-2AG10-0AB0SIEMENS CPU模块 6ES7313-6CF03-0AB0SIEMENS 电源模块 6GK7342-5DA02-0XE0SIEMENS 变频器通讯板 6SE7090-0XX84-0FF5SIEMENS 制动单元 6SE7023-2ES87-2DA1SIEMENS 行走变频器预充电板 6SE7024-7FD84-1HH0SIEMENS 导轨通讯放大器 6ES7972-4AA02-0XA0SIEMENS 变频器 6ES7341-1CH01-0AE0SIEMENS 电源模块 6GK7343-1EX21-0XE0SIEMENS 模块 6ES7321-1BL00-0AA0SIEMENS 模块 6ES7322-1BL00-0AA0SIEMENS 模块 6ES7153-1AA03-0XB0

SIEMENS 模块 6DD1600-OAKOSIEMENS 模块 6DD1611-OAGOSIEMENS 模块 6DD1606-3ACOSIEMENS 模块 6DD1606-4ABOSIEMENS 模块 6DD1645-OADO SIEMENS 模块 6DD2920-OAKOSIEMENS 模块 6DD1662-OABOSIEMENS 模块 6DD1688-OADOSIEMENS 模块 6DD1601-OAHOSIEMENS 模块 6DD1610-0AHOSIEMENS 模块 6SD2281-OAAOOSIEMENS 模块 6DD1681-OCA2SIEMENS 通讯模块 6EP1336-2BAOOSIEMENS 通讯模块 6EP1333-2AAOOSIEMENS 通讯模块 6EP1334-2AAOOSIEMENS 模块 6DD1681-OFGO

SIEMENS 变流器主板 C98043-A7006-L1SIEMENS 变流器主板 C98043-A7001-L2SIEMENS 交流器电子触发板 C98043-A7003-L4SIEMENS 交流器电子触发板 C98043-A7004-L2SIEMENS 交流器电子触发板 6SE7090-0XX84-0KA0SIEMENS 阀门定位器 6DR5010-ONG00-0AA0

SIEMENS CPU模块 6ES7416-3XR05-0AB0SIEMENS 电阻板 6SE7033-2EG84-1BH0SIEMENS IGD模块 6SE7033-2EG84-1JF1SIEMENS 接口模块 6ES7365-0BA01-0AA0SIEMENS CVC模板 6SE7090-0XX84-0AB0SIEMENS 导轨 6ES7390-1AE80-0AA0SIEMENS IVI模板 6SE7031-2HF84-1BG0SIEMENS 电子板 6SE7031-7HG84-1JA1

SIEMENS 通讯处理器 6GK7343-1EX11-0XE0SIEMENS 通讯处理器 6GK7443-1EX20-0XB0 //标准型号为:6GK7443-1EX20-0XE0SIEMENS 西门子变频器基本操作面板 6SE6400-0BP00-0AA0SIEMENS 可编程控制器 6ES7214-2BD23-0XB8SIEMENS 触摸屏 6AV6642-0AA11-0AX00SIEMENS 面板 6SL3055-0AA00-4BA0SIEMENS 面板 6SL3055-0AA00- 3AA0 //已升级为:6SL3055-0AA00-3AA1 SIEMENS 端子面板 6SL3055-0AA00-2TA0SIEMENS 吸收电阻 6SY7000-0AB18 SIEMENS 通讯模块 6SE7090-0XX84-0FF5 SIEMENS 变频器SBP板 6SE7090-0XX84-0FA0SIEMENS 通讯电缆 6ED1057-1AA01-0BA0SIEMENS CUMC板 6SE7090-0XX84-0AD1SIEMENS 连接电缆 6SE7010-0AB3 型号不全SIEMENS 控制板 6SN1118-ODH23-0AA0 //已升级为:6SN1118-ODH23-0AA1SIEMENS 控制板 6SN1118-0DG23-0AA0 //已升级为:6SN1118-0DG23-0AA1SIEMENS 控制器 6SN1118-1NH01-0AA1SIEMENS 控制器 6SN1118-0NH01-0AA0

SIEMENS 双法兰液位变送器 7MF4433-1FYO2-2AC6SIEMENS 双法兰液位变送器 7MF2761-1FD24-0BG1-ZV03SIEMENS 雷达液位 7ML5431-0AF00-0BA0SIEMENS 隔膜密封式压力变送器 7MF4033-1DY00-3AB6 ZA02Y15SIEMENS 隔膜密封式压力变送器 7MF4920-1LA01-5BSIEMENS 阀门定位器 6DR5010-0NG00-0AA0SIEMENS 24V电源模块 6EP1331-1SH02SIEMENS 控制主板 6SE7090-0XX84-0AB0

SIEMENS CPU电池 6ES7971-1AA00-0AA0SIEMENS CPU电池 6ES7971-0BA00SIEMENS 插头 6ES7927-0BB12-0XA0SIEMENS 插头 6ES7972-0BA41-0XA0SIEMENS 手轮 6FX2007-AD02 //已升级为:6FX2007-1AD03 SIEMENS 脉冲板 C98043-A7002-L4-12

SIEMENS 交流器电子触发板 C98043-A7003-L4SIEMENS 交流器励磁电路板 C98043-A7004-L2SIEMENS 交流器通讯板 6SE7090-0XX84-0KA0

SIEMENS CU2模板 6SE7090-0XX84-OAF0替代6SE7090-0XX84-OAB0 SIEMENS CU2模板 6SE7090-0XX84-0AJ0SIEMENS T300 模块 6SE7090-0XX84-OAH2 SIEMENS T300 模块 6SE7098-0XX84-0AH0 SIEMENS 电池 6ES7971-0BA00SIEMENS 光纤连接电缆 6ES7 407-0KR00-0AA0升级为6ES7 407-0KR02-0AA0SIEMENS 光纤连接电缆 6ES7 952-1AL00-0AA0SIEMENS 光纤连接电缆 6ES7 960-1AA00-5AA0SIEMENS 光纤连接电缆 6ES7 960-1AA00-0XA0SIEMENS 接口端子 6ES7193-4CC30-0AA0 SIEMENS CPU 222 CN AC/DC/继电器8 输入/6 输出 6ES7 212-1BB22-0XB8SIEMENS CP 243-1 以太网接口模块 6GK7 243-1EX00-0XE0 //已升级为:6GK7 243-1EX01-0XE0SIEMENS EM 231 CN 模拟量输入模块 4 输入x12 位 6ES7 231-0HC22-0XA8SIEMENS 直流24电源5A 6EP1333-2AA01SIEMENS CPU 224 CN AC/DC/继电器 24 输入/16 输出 6ES7214-1BD23-0XB8SIEMENS CP 243-1 以太网接口模块 6GK7243-1EX01-0XE0SIEMENS EM 235CN 模拟量输入模块 4 输入/1输入x12 位 6ES7235-0KD22-0XA8SIEMENS SITOP 24电源10A 6EP1334-2AA01SIEMENS CPU 226CN AC/DC/继电器 24 输入/16 输出 6ES7216-2BD23-0XB8SIEMENS EM 235CN 模拟量输入模块 4 输入/1输出x12 位 6ES7235-0KD22-0XA8

SIEMENS DI模板 6ES7 321-1FF01-0AA0SIEMENS D0模板 6ES7322-1HF01-0AA0

SIEMENS 伺服模块 6SN1118-0AD11-0AA1SIEMENS 伺服模块 6SN1123-1AA00-0HA1

SIEMENS 二氧华硫传感器 C79451-A3468-B233SIEMENS 斩波器 C79451-A3468-B515SIEMENS 母板 C79451-A3492-B601 升级 C79451-A3494-D501

SIEMENS 输出模块 6ES7 332-5HB01-0AB0SIEMENS 输出模块 6ES7332-5HD01-0AB0SIEMENS 输入模块 6ES7 322-8BF00-0AB0SIEMENS 位置输入模块 6ES7 338-4BC00-0AB0升级 6ES7338-4BC01-0AB0SIEMENS 电池 6ES7971-0BA0SIEMENS PLCPS307模块 6SE7307-1KA01-OAAOSIEMENS CPU315-2DP模块 6SE7315-2AG10-0ABOSIEMENS CPU313C-2DP模块 6ES7313-6CF03-OABOSIEMENS CP342-5模块 6GK7342-5DA02-0XEOSIEMENS DP总线连接器 6ES7972-DBA41-OXAO

SIEMENS 数字输入模块 6ES7321-1BH02-0AA0SIEMENS 数字输入模块 6ES7 321-1BL00-0AA0SIEMENS 数字输出模块 6ES7 322-1BH01-0AA0SIEMENS 数字输出模块 6ES7 322-1BL00-0AA0Siemens 数字输出模块 6ES7 322-1HH01-0AA0

SIEMENS 模块 6ES7138-4CA00-OABOSIEMENS 模块 6ES7132-4BD00-OABOSIEMENS 模块 6SES7134-4JB50-OABOSIEMENS 模块 6SES7 135-4GB01SIEMENS 模块 6SES7321-1BL00-OABOSIEMENS 模块 6SES7322-1HH00-OABOSIEMENS 模块 6SES7 331-7KF02-OABOSIEMENS 模块 6SES7331-5KF00-OABO型号请确认SIEMENS 模块 6SES7332-5HD01-OABOSIEMENS 模块 6ES7277-0AA21-OXA8SIEMENS 模块 6ES7231-7PB22-OXA8SIEMENS 模块 6ES7235-0KD22-OXA8SIEMENS 通讯电缆总线连接器 6ES7972-0BB50-0AA0SIEMENS PROFIBUS通讯电缆线 6XV18300EH10(原装进口)SIEMENS 行走变频器预充电板 6SE7024-7FD84-1HH0SIEMENS 制动单元 6SE7023-2ES87-2DA1SIEMENS 电源板 C98043-a7004-L2-8

SIEMENS CPU 6ES7416-3XL04-OABO 升6ES7416-3XR05-0AB0

SIEMENS AI模块 6ES7331-7NF00-OABOSIEMENS 扩展模块 6ED1055-1FB00-0BA1SIEMENS 电池 6ES7971-0BA00

SIEMENS 西门子风机 6SY7000-0AB30SIEMENS 西门子风机 6SY7000-0AB28SIEMENS 西门子风扇 EWN:8399501416000SIEMENS 西门子风扇 EWN:8399501418000SIEMENS 西门子风扇 A5E00253147停产升级型号:A5E00829151SIEMENS 西门子风扇 EWN:5193000903000SIEMENS 西门子风扇 EWN:5193000901000SIEMENS 西门子风扇 EWN:5193016203000

SIEMENS 西门子PLC数字输入 6ES7321-1BH02-0AA0 16点,24VDCSIEMENS 西门子PLC数字输出 6ES7 322-1BH02-0AA0正确型号:6ES7 322-1BH01-0AA0SIEMENS 西门子PLC输入 6ES7 334-OCE01-OAAO SIEMENS 模块 6ES7307-1EA00-0AA0 PS307SIEMENS 模块 6ES7315-2AG10-0AB0 CPU315-2DPSIEMENS 模块 6ES7331-7KF02-0AB0SIEMENS 模块 6ES7331-7PF00-0AB0升级6ES7331-7PF01-0AB0SIEMENS 模块 6ES7321- 1BL00-0AA0SIEMENS 模块 6ES7321-1BH02-0AA0(DI) SIEMENS 模块 6ES7322-1BL00-0AA0(D0)SIEMENS 模块 6ES7307-1EA01-0AA0SIEMENS 模块 6ES7315-2AH14-0AB0SIEMENS 斩波器 6SE7032-5FB87-2DA0//已升级为:6SE7032-5FB87-2DA1

SIEMENS 通讯模块 6ES7214-1AD23-0XB0SIEMENS 通讯模块 6ES7231-0HC22-0XA0SIEMENS 电源模块 6ES7407-0KR02-0AA0SIEMENS 背板总线 6ES7400-1TA01-0AA0

SIEMENS 电源 6EP1336-2BA00SIEMENS 电源转换模块 6EP1336-3BA00SIEMENS 模块 6EP1437-2BA10 //已升级为:6EP1437-2BA20SIEMENS 电源 6EP1437-3BA00SIEMENS 模块 6ES7158-0AD01-0XA0

SIEMENS 压力变送器 7MF1564-3DD00-1AA1SIEMENS 液位计 7ML1201-1EF00SIEMENS 水位计 7MF1570-1CA01SIEMENS 超声波液位计 7ML5221-1BA11 SIEMENS 超声波液位计 7ML1201-1EF00 测量范围:0.25-5.0m,两线制,4-20mA信号,分辨率:3mmSiemens 变送器 7MF1563-3CE00-1AA1 //已升级为:7MF1564-3CE00-1AA1

FM801FM801主控单元

供应和利时模块 QQ:642706330 供应和利时模块 型号齐全,欢迎来电咨询!www.zbxinshuo 客服[1](QQ 389924996)

客服[1](QQ 389924996)  客服[4](QQ 642706330)

客服[4](QQ 642706330) FM131A FM138-DCC FM138-DCD FM138-SSR FM141 FM142 FM143 FM143A FM143G FM144A FM145B FM146A FM1305-A FM147A FM148 FM148C FM148E FM148R FM151A FM131AR-AI-I FM131-C FM131-D FM131-E-A FM131-DEH FM131A-DEH-B FM132 FM133 FM134 FM136 FM138-ACC FM138-ACD FM151R FM152A FM161D FM161D-SOE FM161D-48 FM161D-48-SOE FM161E-48-SOE FM162 FM163A FM165 FM171 FM171B FM181 FM182 FM182A FM191 FM191A FM191A-A FM192A-CC FM192B-CC FM192A-TR FM197 FM811-K01 FM811-SP-K01 FM801 FM803 FM300-A FM301 FM305-A FM910 FM920 FM931 FB121 FB136 FB137 FB138-DC-B FB138-AC-B FB138-SSR-C FB139 FB149-D FB193 FB194 FB196 FB197 FM111 FM111R FM112 FM112R FM113(计算机;SSC5X86H/32M EDO/8MB DOC) FM113R FM114 FM1200 FM1201 FM1202-B FM1303 PE1800 GX280 GX520nSMT

FM131A FM138-DCC FM138-DCD FM138-SSR FM141 FM142 FM143 FM143A FM143G FM144A FM145B FM146A FM1305-A FM147A FM148 FM148C FM148E FM148R FM151A FM131AR-AI-I FM131-C FM131-D FM131-E-A FM131-DEH FM131A-DEH-B FM132 FM133 FM134 FM136 FM138-ACC FM138-ACD FM151R FM152A FM161D FM161D-SOE FM161D-48 FM161D-48-SOE FM161E-48-SOE FM162 FM163A FM165 FM171 FM171B FM181 FM182 FM182A FM191 FM191A FM191A-A FM192A-CC FM192B-CC FM192A-TR FM197 FM811-K01 FM811-SP-K01 FM801 FM803 FM300-A FM301 FM305-A FM910 FM920 FM931 FB121 FB136 FB137 FB138-DC-B FB138-AC-B FB138-SSR-C FB139 FB149-D FB193 FB194 FB196 FB197 FM111 FM111R FM112 FM112R FM113(计算机;SSC5X86H/32M EDO/8MB DOC) FM113R FM114 FM1200 FM1201 FM1202-B FM1303 PE1800 GX280 GX520nSMT

7100L(EUROTHERM)欧陆7100L单相固态接触器

如有需要请在QQ上留言,谢谢!

西门子G110 交流变频器

VGT-2127QTDVGT-2127QTD数控超声波清洗机

产品特点:

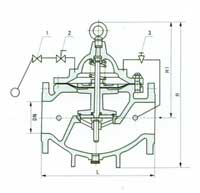

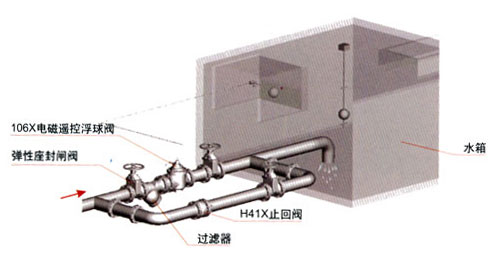

100X遥控浮球阀 遥控浮球阀 浮球阀 水力控制阀

安装示意图:

安装示意图:

| DN | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| L | 230 | 240 | 285 | 325 | 360 | 400 | 470 | 575 | 640 | 700 | 740 |

| H | 225 | 300 | 320 | 420 | 450 | 500 | 710 | 770 | 905 | 970 | 1000 |

HD3051DP/GPHD3051DP/GP压力变送器哪家好便宜厂家直销

江苏仪华牌HD3051DP/GP压力变送器哪家好销售、HD3051DP/GP压力变送器哪家好厂家、HD3051DP/GP压力变送器哪家好。

HD3051DP/GP压力变送器哪家好公司简介:江苏仪华测控仪表有限公司主要生产各种型号的压力变送器、压力传感器、物位计、料位计、磁翻板物位计、温度仪表、压力仪表、物位仪表、控制开关、电热带配件等产品。是历史三十多年的仪表仪器行业中的大型企业,被国家列入大型一档企业,并被例入中国电力企业家协会火电分会成员,化工产业定点企业。被化工部、机电部、冶金工业部推荐为质量信得过产品企业。由于仪华的诚信和努力,长期来在供求双方之间保持着很高的信誉和良好的沟通渠道。企业连续多年被有关部门评为“重合同,守信用”单位。一、HD3051DP/GP压力变送器哪家好简介:高温高压型导波雷达液位计说明书,高温高压型导波雷达液位计价格,高温高压型导波雷达液位计 供应CDGW540高温高压导波雷达液位计仪华测控仪表有限公司导波雷达发出的高频微波脉冲沿着探测组件(钢缆或钢棒)传播,遇到被测介质,由于介电常数突变,引起反射,一部分脉冲能量被反射回来。发射脉冲与反射脉冲的时间间隔与到被测介质的距离成正比。 容器中存在两种不同介质,当上面一层的介质介电常数较小,而下面的介质介电常数较大时,高频微波脉冲沿着探测组件传播遇到上层介质时,由于其介电常数较小,因而有极少的能量被这一层介面反射,而大部分能量穿透上层介质继续向下传播,遇到两层的介面时,由于下层介质的介电常数较大,因而会有较大的能量被反射回来。因而导波雷达是可以测量两种不同介质的介面,其测量条件是上层介质不导电或其介电常数比下层介质介电常数小10以上。 特 点 由于采用了先进的微波处理器和独特的EchoDiscovery回波处理技术,导波雷达物位计可以应用于各种复杂工况。 多种过程连接方式及探测组件的型式,使得CDGW系列导波雷达物位计适用于各种复杂工况。如:高温、高压及小介电常数介质等。为了方便您更详细了解产品,仪华测控专门制作了压力变送器展示平台,此平台主要展示产品为压力变送器,也有很多压力变送器的产品图片。但是希望客户不要因为产品图片而误导订货方向,我们整理的图片并不能代表你订购的产品,因为根据产品的型号以及功能不同,样式也是不一样的,还请谅解。展示网址www.0523yh.com1、压力变送器如何选型 首先要确认要测量什么样的压力先确定系统中测量压力的最大值,一般而言需要选择一个具有比最大值还要大1.5倍左右的压力量程的变送器。这主要是在许多系统中,尤其是水压测量和加工处理中,有峰值和持续不规则的上下波动,这种瞬间的峰值能破坏压力传感器。持续的高压力值或稍微超出变送器的标定最大值会缩短传感器的寿命,这样做还会使精度下降。于是可以用一个缓冲器来降低压力毛刺,但这样会降低传感器的响应速度。所以在选择变送器时要充分考虑压力范围、精度与其稳定性。2、什么样的压力介质黏性液体、泥浆会堵上压力接口,溶剂或有腐蚀性的物质会不会破坏变送器中与这些介质直接接触的材料。以上这些因素将决定是否选择直接的隔离膜及直接与介质接触的材料。3、压力变送器需要多大的精度决定精度的有,非线性,迟滞性,非重复性,温度、零点偏置刻度,温度的影响。但主要由非线性,迟滞性,非重复性,精度越高,价格也就越高

scientz-192高通量组织研磨器

原理:

在装样品的碾磨罐或离心管中加入小钢珠(或氧化锆球),研磨罐或适配器垂直方向振动,在高频振动作用下,小球高速击打样品来完成样品的研磨。

采用研磨球进行研磨,使得样品的研磨相较于传统的研磨方式更为均匀、充分。采用高通量组织研磨器,还可以作为匀浆器在研磨罐中加入钢球和细胞珠可有效的破碎超声波高压破碎难以破碎的细胞,利用高密度小钢珠或者氧化锆珠子迅速分散样品。

专利号:200910101884.9

| 电源 | 220v/50HZ |

| 功率 | 375W |

| 行程 | 32mm |

| 速率 | 50-2000次/分钟可调 |

| 样品容量 | 随机配置1ml-2ml适配器2×48孔; 可选配0.2ml-0.5ml适配器2×96孔;5ml的适配器2×24孔;适配器固定夹可夹96孔酶板4×96孔 |

| 外机尺寸 | L514×W380×H520mm |

| 保护 | 开盖保护 |

随机配100颗5mm不锈钢球,可选配铁球、氧化锆球及玻璃珠、带制冷源适配器。

最新产品

- CEME高压电磁阀维修干货分享 2025/12/15 13:49:40

- E+L 灯具 2025/12/15 13:49:04

- 健来邦麻醉呼吸回路消毒机JLB-88-D 2025/12/15 13:48:36

- VFF41.900西门子蝶阀(维修)体验感好 2025/12/15 13:48:19

- E+L 纠编电缸 2025/12/15 13:48:04

- LPDDR5 时钟异常,DDR4 速率不达标,时钟抖动排查,JEDEC JESD79-4/JESD209-5 合规,多通道同步故障 2025/12/15 13:48:00

- TITANS TVA-A 泰坦数字式电压表TITANS TVA-A-1 泰坦 数字式电流表 2025/12/15 13:47:46

- E+L 驱动器 2025/12/15 13:47:04

- PARKER电磁阀烧坏维修低流量 2025/12/15 13:46:58

- 韩国I-TORK 角行程电动执行器 ITQ 0800系列 支持选型 2025/12/15 13:46:57

- 数显表 Display Unit 2025/12/15 13:46:15

- E+L 张力放大器 2025/12/15 13:46:04

- 沃斯特蝶阀密封面泄漏维修服务细致 2025/12/15 13:45:40

- E+L 备件 2025/12/15 13:45:03

- AUTORUN蝶阀不工作维修实用妙招 2025/12/15 13:44:28

- E+L 备件 2025/12/15 13:44:03

- SUNYEH山野蝶阀维修基础讲解 2025/12/15 13:43:11

- E+L 备件 2025/12/15 13:43:03

- 真空密封性能测试仪 2025/12/15 13:42:42

- 药品泡罩包装密封性测试仪 2025/12/15 13:42:15

- 牧歌电磁阀维修实用妙招 2025/12/15 13:42:08

- E+L CPP二线测厚仪摆动 2025/12/15 13:42:03

- 药品包装密封性测试仪 2025/12/15 13:41:58

- 包装密封性测试仪 2025/12/15 13:41:45

- 连续式米糠油精炼设备,毛油脱胶脱酸脱臭脱蜡,大型浸出油炼油设备 2025/12/15 13:41:44

- 软包装密封性能测试仪 2025/12/15 13:41:35

- 负压密封性测试仪 2025/12/15 13:41:20

- E+L 传感器 2025/12/15 13:41:03

- 美国MILLER电磁阀烧坏维修油缸下降不稳 2025/12/15 13:40:56

- 全自动密封性测试仪 2025/12/15 13:40:33